Page 262 - Sustainability in the Process Industry Integration and Optimization

P. 262

E x a m p l e s a n d Ca s e S t u d i e s 239

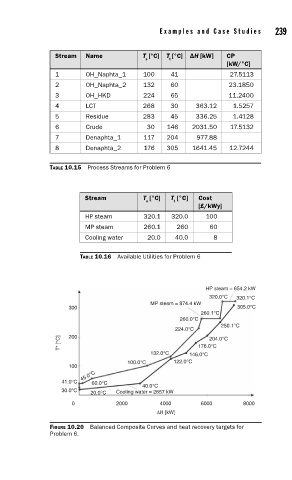

Stream Name T [°C] T [°C] ΔH [kW] CP

s t

[kW/°C]

1 OH_Naphta_1 100 41 27.5113

2 OH_Naphta_2 132 60 23.1850

3 OH_HKD 224 65 11.2400

4 LCT 268 30 363.12 1.5257

5 Residue 283 45 336.25 1.4128

6 Crude 30 146 2031.50 17.5132

7 Denaphta_1 117 204 977.88

8 Denaphta_2 176 305 1641.45 12.7244

TABLE 10.15 Process Streams for Problem 6

Stream T [°C] T [°C] Cost

s t

[£/kWy]

HP steam 320.1 320.0 100

MP steam 260.1 260 60

Cooling water 20.0 40.0 8

TABLE 10.16 Available Utilities for Problem 6

HP steam = 654.2 kW

320.0°C 320.1°C

MP steam = 874.4 kW

300 305.0°C

260.1°C

260.0°C

250.1°C

224.0°C

T* [°C] 200 176.0°C

204.0°C

132.0°C 146.0°C

100.0°C 122.0°C

100

45.0°C

41.0°C 60.0°C

40.0°C

30.0°C

20.0°C Cooling water = 2657 kW

0 2000 4000 6000 8000

ΔH [kW]

FIGURE 10.20 Balanced Composite Curves and heat recovery targets for

Problem 6.