Page 71 - Sustainability in the Process Industry Integration and Optimization

P. 71

48 Cha p te r F o u r

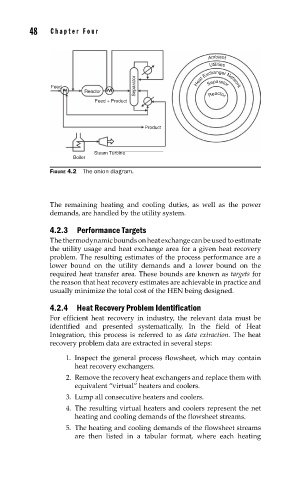

Ambient

Utilities

Separator Separator

Feed Heat Exchanger Network

Reactor

Feed + Product Reactor

Product

Steam Turbine

Boiler

FIGURE 4.2 The onion diagram.

The remaining heating and cooling duties, as well as the power

demands, are handled by the utility system.

4.2.3 Performance Targets

The thermodynamic bounds on heat exchange can be used to estimate

the utility usage and heat exchange area for a given heat recovery

problem. The resulting estimates of the process performance are a

lower bound on the utility demands and a lower bound on the

required heat transfer area. These bounds are known as targets for

the reason that heat recovery estimates are achievable in practice and

usually minimize the total cost of the HEN being designed.

4.2.4 Heat Recovery Problem Identification

For efficient heat recovery in industry, the relevant data must be

identified and presented systematically. In the field of Heat

Integration, this process is referred to as data extraction. The heat

recovery problem data are extracted in several steps:

1. Inspect the general process flowsheet, which may contain

heat recovery exchangers.

2. Remove the recovery heat exchangers and replace them with

equivalent “virtual” heaters and coolers.

3. Lump all consecutive heaters and coolers.

4. The resulting virtual heaters and coolers represent the net

heating and cooling demands of the flowsheet streams.

5. The heating and cooling demands of the flowsheet streams

are then listed in a tabular format, where each heating