Page 73 - Sustainability in the Process Industry Integration and Optimization

P. 73

50 Cha p te r F o u r

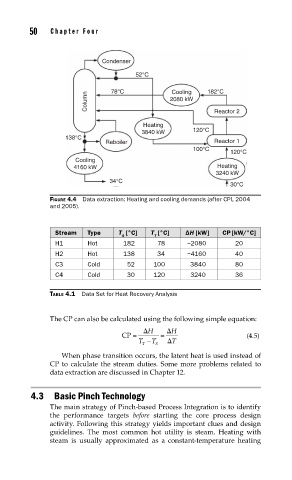

Condenser

52°C

Cooling

Column 78°C 2080 kW 182°C

Reactor 2

Heating

3840 kW 120°C

138°C

Reboiler Reactor 1

100°C

120°C

Cooling

4160 kW Heating

3240 kW

34°C

30°C

FIGURE 4.4 Data extraction: Heating and cooling demands (after CPI, 2004

and 2005).

Stream Type T [°C] T [°C] ΔH [kW] CP [kW/°C]

S T

H1 Hot 182 78 −2080 20

H2 Hot 138 34 −4160 40

C3 Cold 52 100 3840 80

C4 Cold 30 120 3240 36

TABLE 4.1 Data Set for Heat Recovery Analysis

The CP can also be calculated using the following simple equation:

H H

CP (4.5)

T T S T

T

When phase transition occurs, the latent heat is used instead of

CP to calculate the stream duties. Some more problems related to

data extraction are discussed in Chapter 12.

4.3 Basic Pinch Technology

The main strategy of Pinch-based Process Integration is to identify

the performance targets before starting the core process design

activity. Following this strategy yields important clues and design

guidelines. The most common hot utility is steam. Heating with

steam is usually approximated as a constant-temperature heating