Page 56 - Materials Chemistry, Second Edition

P. 56

Ch002-P373623.qxd 3/22/07 5:27 PM Page 37

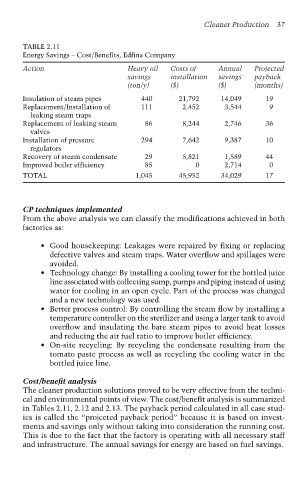

TABLE 2.11 Cleaner Production 37

Energy Savings – Cost/Benefits, Edfina Company

Action Heavy oil Costs of Annual Projected

savings installation savings payback

(ton/y) ($) ($) (months)

Insulation of steam pipes 440 21,792 14,049 19

Replacement/Installation of 111 2,452 3,544 9

leaking steam traps

Replacement of leaking steam 86 8,244 2,746 36

valves

Installation of pressure 294 7,642 9,387 10

regulators

Recovery of steam condensate 29 5,821 1,589 44

Improved boiler efficiency 85 0 2,714 0

TOTAL 1,045 45,952 34,029 17

CP techniques implemented

From the above analysis we can classify the modifications achieved in both

factories as:

• Good housekeeping: Leakages were repaired by fixing or replacing

defective valves and steam traps. Water overflow and spillages were

avoided.

• Technology change: By installing a cooling tower for the bottled juice

line associated with collecting sump, pumps and piping instead of using

water for cooling in an open cycle. Part of the process was changed

and a new technology was used.

• Better process control: By controlling the steam flow by installing a

temperature controller on the sterilizer and using a larger tank to avoid

overflow and insulating the bare steam pipes to avoid heat losses

and reducing the air fuel ratio to improve boiler efficiency.

• On-site recycling: By recycling the condensate resulting from the

tomato paste process as well as recycling the cooling water in the

bottled juice line.

Cost/benefit analysis

The cleaner production solutions proved to be very effective from the techni-

cal and environmental points of view. The cost/benefit analysis is summarized

in Tables 2.11, 2.12 and 2.13. The payback period calculated in all case stud-

ies is called the “projected payback period” because it is based on invest-

ments and savings only without taking into consideration the running cost.

This is due to the fact that the factory is operating with all necessary staff

and infrastructure. The annual savings for energy are based on fuel savings.