Page 192 -

P. 192

Pump Installation a Piping

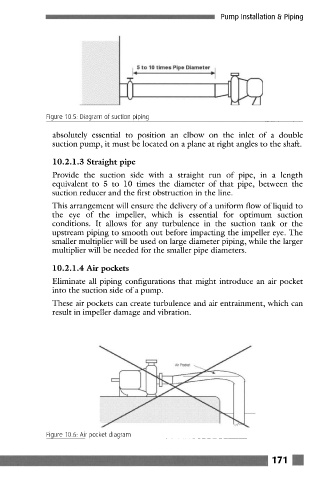

1 5 to 10 times Pipe Diameter I

Figure 10.5-Diagram of suction piping

absolutely essential to position an elbow on the inlet of a double

suction pump, it must be located on a plane at right angles to the shaft.

10.2.1.3 Straight pipe

Provide the suction side with a straight run of pipe, in a length

equivalent to 5 to 10 times the diameter of that pipe, between the

suction reducer and the first obstruction in the line.

This arrangement will ensure the delivery of a uniform flow of liquid to

the eye of the impeller, which is essential for optimum suction

conditions. It allows for any turbulence in the suction tank or the

upstream piping to smooth out before impacting the impeller eye. The

smaller multiplier will be used on large diameter piping, while the larger

multiplier will be needed for the smaller pipe diameters.

10.2.1.4 Air pockets

Eliminate all piping configurations that might introduce an air pocket

into the suction side of a pump.

These air pockets can create turbulence and air entrainment, which can

result in impeller damage and vibration.

Air Pod~et

ii!i iii li iii ! iii!iiZili!i i!ii i i iii iii ii i ii i iili! ! i!! ii !iii iil iii!ii!i iii !iiiiil iii~ ~

i i i iil ~i~iii~i~ii~ii~!ii~!iiii~!ii~i~i~i~iiiii~ii!iiiiii~i~ii~ii~i~iiii~!iii~iiii~!~i!~iiiiiiiiii~iiiii~!~iiiiiii~i~!~ii~i~i~iii~i~i~!ii~iii~ii~ii~i~i~iiiii~i

Figure 10.6-Air pocket diagram

171 m