Page 195 -

P. 195

The Practical Pumping Handbook ...........

t

2

m

Recirculation Line By-Pass -~

Valve i

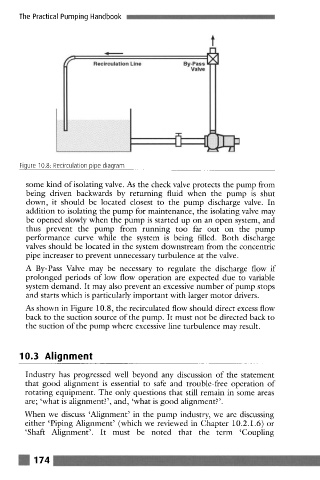

Figure 10.8: Recirculation pipe diagram

some kind of isolating valve. As the check valve protects the pump from

being driven backwards by returning fluid when the pump is shut

down, it should be located closest to the pump discharge vane. In

addition to isolating the pump for maintenance, the isolating vane may

be opened slowly when the pump is started up on an open system, and

thus prevent the pump from running too far out on the pump

performance curve while the system is being filled. Both discharge

valves should be located in the system downstream from the concentric

pipe increaser to prevent unnecessary turbulence at the valve.

A By-Pass Valve may be necessary to regulate the discharge flow if

prolonged periods of low flow operation arc expected due to variable

system demand. It may also prevent an excessive number of pump stops

and starts which is particularly important with larger motor drivers.

As shown in Figure 10.8, the recirculated flow should direct excess flow

back to the suction source of the pump. It must not be directed back to

the suction of the pump where excessive line turbulence may result.

10.3 Alignment

Industry has progressed well beyond any discussion of the statement

that good alignment is essential to safe and trouble-free operation of

rotating equipment. The only questions that still remain in some areas

are; 'what is alignment?', and, 'what is good alignment?'.

When we discuss 'Alignment' in the pump industry, we are discussing

either 'Piping Alignment' (which we reviewed in Chapter 10.2.1.6) or

'Shaft Alignment'. It must be noted that the term 'Coupling

174