Page 202 - The Six Sigma Project Planner

P. 202

treated rather than their underlying “diseases.” For example, if quality problems cause

schedule slippages that lead to customer complaints, the “solution” might be to keep a

large inventory and sort the good from the bad. The result is that the schedule is met

and customers stop complaining, but at huge cost. These opportunities are often greater

than those currently causing “pain,” but they are now built into business systems and

therefore very difficult to see. One solution to the hidden problem phenomenon is to

focus on processes rather than symptoms. Some guidelines for identifying

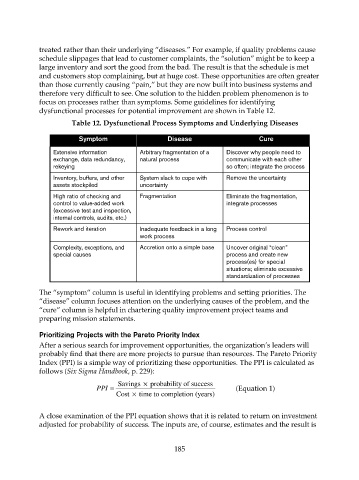

dysfunctional processes for potential improvement are shown in Table 12.

Table 12. Dysfunctional Process Symptoms and Underlying Diseases

Symptom Disease Cure

Extensive information Arbitrary fragmentation of a Discover why people need to

exchange, data redundancy, natural process communicate with each other

rekeying so often; integrate the process

Inventory, buffers, and other System slack to cope with Remove the uncertainty

assets stockpiled uncertainty

High ratio of checking and Fragmentation Eliminate the fragmentation,

control to value-added work integrate processes

(excessive test and inspection,

internal controls, audits, etc.)

Rework and iteration Inadequate feedback in a long Process control

work process

Complexity, exceptions, and Accretion onto a simple base Uncover original “clean”

special causes process and create new

process(es) for special

situations; eliminate excessive

standardization of processes

The “symptom” column is useful in identifying problems and setting priorities. The

“disease” column focuses attention on the underlying causes of the problem, and the

“cure” column is helpful in chartering quality improvement project teams and

preparing mission statements.

Prioritizing Projects with the Pareto Priority Index

After a serious search for improvement opportunities, the organization’s leaders will

probably find that there are more projects to pursue than resources. The Pareto Priority

Index (PPI) is a simple way of prioritizing these opportunities. The PPI is calculated as

follows (Six Sigma Handbook, p. 229):

×

PPI = Savings probability of success (Equation 1)

×

Cost time to completion (years)

A close examination of the PPI equation shows that it is related to return on investment

adjusted for probability of success. The inputs are, of course, estimates and the result is

185