Page 419 - The Mechatronics Handbook

P. 419

0066_frame_C19 Page 41 Wednesday, January 9, 2002 5:17 PM

+

-

(a)

+

-

(b)

+

(c) -

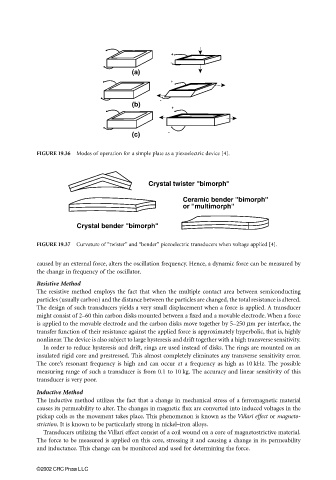

FIGURE 19.36 Modes of operation for a simple plate as a piezoelectric device [4].

Crystal twister ''bimorph''

Ceramic bender ''bimorph''

or ''multimorph''

Crystal bender ''bimorph''

FIGURE 19.37 Curvature of “twister” and “bender” piezoelectric transducers when voltage applied [4].

caused by an external force, alters the oscillation frequency. Hence, a dynamic force can be measured by

the change in frequency of the oscillator.

Resistive Method

The resistive method employs the fact that when the multiple contact area between semiconducting

particles (usually carbon) and the distance between the particles are changed, the total resistance is altered.

The design of such transducers yields a very small displacement when a force is applied. A transducer

might consist of 2–60 thin carbon disks mounted between a fixed and a movable electrode. When a force

is applied to the movable electrode and the carbon disks move together by 5–250 µm per interface, the

transfer function of their resistance against the applied force is approximately hyperbolic, that is, highly

nonlinear. The device is also subject to large hysteresis and drift together with a high transverse sensitivity.

In order to reduce hysteresis and drift, rings are used instead of disks. The rings are mounted on an

insulated rigid core and prestressed. This almost completely eliminates any transverse sensitivity error.

The core’s resonant frequency is high and can occur at a frequency as high as 10 kHz. The possible

measuring range of such a transducer is from 0.1 to 10 kg. The accuracy and linear sensitivity of this

transducer is very poor.

Inductive Method

The inductive method utilizes the fact that a change in mechanical stress of a ferromagnetic material

causes its permeability to alter. The changes in magnetic flux are converted into induced voltages in the

pickup coils as the movement takes place. This phenomenon is known as the Villari effect or magneto-

striction. It is known to be particularly strong in nickel–iron alloys.

Transducers utilizing the Villari effect consist of a coil wound on a core of magnetostrictive material.

The force to be measured is applied on this core, stressing it and causing a change in its permeability

and inductance. This change can be monitored and used for determining the force.

©2002 CRC Press LLC