Page 598 - The Mechatronics Handbook

P. 598

0066_Frame_C20 Page 68 Wednesday, January 9, 2002 5:49 PM

FIGURE 20.93 Rotary vane pump.

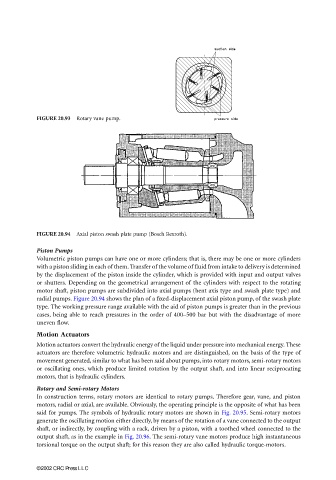

FIGURE 20.94 Axial piston swash plate pump (Bosch Rexroth).

Piston Pumps

Volumetric piston pumps can have one or more cylinders; that is, there may be one or more cylinders

with a piston sliding in each of them. Transfer of the volume of fluid from intake to delivery is determined

by the displacement of the piston inside the cylinder, which is provided with input and output valves

or shutters. Depending on the geometrical arrangement of the cylinders with respect to the rotating

motor shaft, piston pumps are subdivided into axial pumps (bent axis type and swash plate type) and

radial pumps. Figure 20.94 shows the plan of a fixed-displacement axial piston pump, of the swash plate

type. The working pressure range available with the aid of piston pumps is greater than in the previous

cases, being able to reach pressures in the order of 400–500 bar but with the disadvantage of more

uneven flow.

Motion Actuators

Motion actuators convert the hydraulic energy of the liquid under pressure into mechanical energy. These

actuators are therefore volumetric hydraulic motors and are distinguished, on the basis of the type of

movement generated, similar to what has been said about pumps, into rotary motors, semi-rotary motors

or oscillating ones, which produce limited rotation by the output shaft, and into linear reciprocating

motors, that is hydraulic cylinders.

Rotary and Semi-rotary Motors

In construction terms, rotary motors are identical to rotary pumps. Therefore gear, vane, and piston

motors, radial or axial, are available. Obviously, the operating principle is the opposite of what has been

said for pumps. The symbols of hydraulic rotary motors are shown in Fig. 20.95. Semi-rotary motors

generate the oscillating motion either directly, by means of the rotation of a vane connected to the output

shaft, or indirectly, by coupling with a rack, driven by a piston, with a toothed wheel connected to the

output shaft, as in the example in Fig. 20.96. The semi-rotary vane motors produce high instantaneous

torsional torque on the output shaft; for this reason they are also called hydraulic torque-motors.

©2002 CRC Press LLC