Page 169 - Tribology in Machine Design

P. 169

Friction, lubrication and wear in lower kinematic pairs 155

same time, the coefficient of adhesion component of friction under dry

conditions is seriously reduced to a value less than unity as the area of

contact is reduced by the grooves. Nevertheless, the overall effective

coefficient of friction under wet conditions is considerably increased; a

value of/=0.4 for locked wheel skidding on a wet road is typical. The main

role of the grooving on the surface of the tyre is to drain excess water from

the tyre footprint in order to increase the adhesion component of friction.

Thus, an adequate tread pattern offers a compromise between the higher

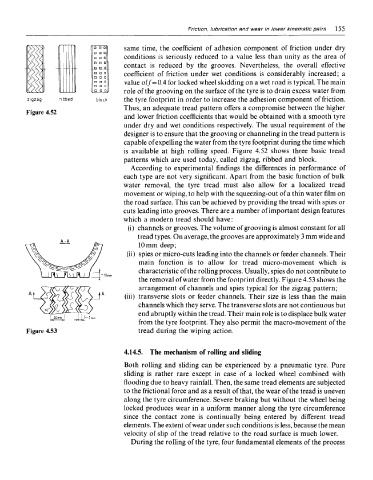

Figure 4.52

and lower friction coefficients that would be obtained with a smooth tyre

under dry and wet conditions respectively. The usual requirement of the

designer is to ensure that the grooving or channeling in the tread pattern is

capable of expelling the water from the tyre footprint during the time which

is available at high rolling speed. Figure 4.52 shows three basic tread

patterns which are used today, called zigzag, ribbed and block.

According to experimental findings the differences in performance of

each type are not very significant. Apart from the basic function of bulk

water removal, the tyre tread must also allow for a localized tread

movement or wiping, to help with the squeezing-out of a thin water film on

the road surface. This can be achieved by providing the tread with spies or

cuts leading into grooves. There are a number of important design features

which a modern tread should have:

(i) channels or grooves. The volume of grooving is almost constant for all

tread types. On average, the grooves are approximately 3 mm wide and

10mm deep;

(ii) spies or micro-cuts leading into the channels or feeder channels. Their

main function is to allow for tread micro-movement which is

characteristic of the rolling process. Usually, spies do not contribute to

the removal of water from the footprint directly. Figure 4.53 shows the

arrangement of channels and spies typical for the zigzag pattern;

(iii) transverse slots or feeder channels. Their size is less than the main

channels which they serve. The transverse slots are not continuous but

end abruptly within the tread. Their main role is to displace bulk water

from the tyre footprint. They also permit the macro-movement of the

Figure 4.53 tread during the wiping action.

4.14.5. The mechanism of rolling and sliding

Both rolling and sliding can be experienced by a pneumatic tyre. Pure

sliding is rather rare except in case of a locked wheel combined with

flooding due to heavy rainfall. Then, the same tread elements are subjected

to the frictional force and as a result of that, the wear of the tread is uneven

along the tyre circumference. Severe braking but without the wheel being

locked produces wear in a uniform manner along the tyre circumference

since the contact zone is continually being entered by different tread

elements. The extent of wear under such conditions is less, because the mean

velocity of slip of the tread relative to the road surface is much lower.

During the rolling of the tyre, four fundamental elements of the process