Page 174 - Tribology in Machine Design

P. 174

160 Tribology in machine design

however, than/=0. There is, however, the problem of energy-loss in the

rolling of the tyre. As the tyre rolls over the road the rubber is cyclically

loaded and unloaded in the contact zone. The energy lost in rolling thus

also depends on the hysteresis losses in the rubber. Indeed the rolling

resistance will increase more or less in the same way as the skid resistance,

i.e. a skid resistant tyre will consume more fuel during rolling. At the early

stages of a research programme aimed to improve the performance of a tyre

it was suggested that this could be overcome by making the main structure

of the tyre of a low-loss rubber to give low-energy consumption in rolling,

and then moulding on a thin surface layer of a high-loss rubber for the

tread. A much neater solution to the problem was provided by R. Bond of

Dunlop. He observed that during braking or during skidding the deform-

ation of the rubber by surface asperities involves rather high-frequency

loading-unloading cycles and considerable local heat generation. On the

other hand, the asperity and bulk deformation of the tyre as it rolls over the

road is a relatively low-frequency process and there is little bulk heating. He

argued that it should thus be possible to produce a rubber which has high

losses at high frequencies and elevated temperatures and low losses at low

frequencies and modest temperatures. A new polymer with a unique micro-

structure that secures the required properties was developed and thus a new

type of tyre was produced that provides both a better grip and a lower fuel

consumption.

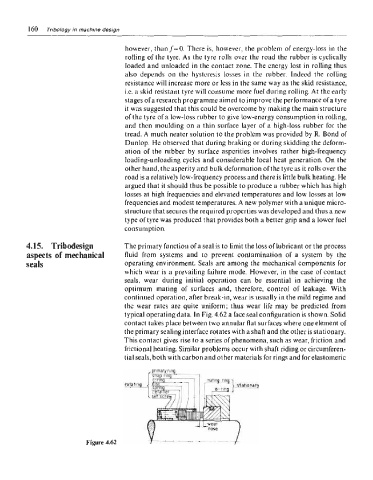

4.15. Tribodesign The primary function of a seal is to limit the loss of lubricant or the process

aspects of mechanical fluid from systems and to prevent contamination of a system by the

seals operating environment. Seals are among the mechanical components for

which wear is a prevailing failure mode. However, in the case of contact

seals, wear during initial operation can be essential in achieving the

optimum mating of surfaces and, therefore, control of leakage. With

continued operation, after break-in, wear is usually in the mild regime and

the wear rates are quite uniform; thus wear life may be predicted from

typical operating data. In Fig. 4.62 a face seal configuration is shown. Solid

contact takes place between two annular flat surfaces where one element of

the primary sealing interface rotates with a shaft and the other is stationary.

This contact gives rise to a series of phenomena, such as wear, friction and

frictional heating. Similar problems occur with shaft riding or circumferen-

tial seals, both with carbon and other materials for rings and for elastomeric

Figure 4.62