Page 173 - Tribology in Machine Design

P. 173

Friction, lubrication and wear in lower kinematic pairs 159

rolling and sliding under the dynamic hydroplaning conditions. When, at a

certain speed, V r, viscous hydroplaning conditions are reached, the

interaction between the tyre and the ground rapidly decreases to a low

value which is just sufficient to balance the load reaction eccentricity torque

but not to rotate the tyre. This is characteristic for locked wheel sliding at a

speed, V r, which is significantly lower than the velocity, K d, at which the

dynamic hydroplaning is established.

4.14.7. The development of tyres with improved performance

As stated earlier, automobile tyres are very complex structures and many

advances have been made in the fabrication, the type of ply, the material of

the cords, the nature of the rubber and the tread pattern. As a result,

modern tyres have achieved greater fuel economy and longer life than those

available say some 30 years ago.

Tribology has made a significant contribution to the development of a

tyre that is more skid resistant and at the same time achieves a further

reduction in fuel consumption. The friction between the tyre and the road

surface consists of two main parts. The first and major component arises

from atomic forces across the interface. The bonds formed between the tyre

and the road surface have to be broken for sliding to occur. Although the

interfacial forces are not particularly strong, rubber has a relatively small

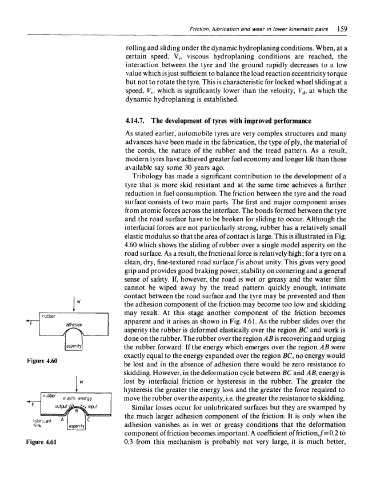

elastic modulus so that the area of contact is large. This is illustrated in Fig.

4.60 which shows the sliding of rubber over a single model asperity on the

road surface. As a result, the frictional force is relatively high; for a tyre on a

clean, dry, fine-textured road surface/is about unity. This gives very good

grip and provides good braking power, stability on cornering and a general

sense of safety. If, however, the road is wet or greasy and the water film

cannot be wiped away by the tread pattern quickly enough, intimate

contact between the road surface and the tyre may be prevented and then

the adhesion component of the friction may become too low and skidding

may result. At this stage another component of the friction becomes

apparent and it arises as shown in Fig. 4.61. As the rubber slides over the

asperity the rubber is deformed elastically over the region EC and work is

done on the rubber. The rubber over the region AB is recovering and urging

the rubber forward. If the energy which emerges over the region AB were

exactly equal to the energy expanded over the region BC, no energy would

Figure 4.60

be lost and in the absence of adhesion there would be zero resistance to

skidding. However, in the deformation cycle between BC and AB, energy is

lost by interfacial friction or hysteresis in the rubber. The greater the

hysteresis the greater the energy loss and the greater the force required to

move the rubber over the asperity, i.e. the greater the resistance to skidding.

Similar losses occur for unlubricated surfaces but they are swamped by

the much larger adhesion component of the friction. It is only when the

adhesion vanishes as in wet or greasy conditions that the deformation

component of friction becomes important. A coefficient of friction,/=0.2 to

Figure 4.61 0.3 from this mechanism is probably not very large, it is much better,