Page 209 - Understanding Automotive Electronics

P. 209

2735 | CH 6 Page 196 Tuesday, March 10, 1998 1:10 PM

6 SENSORS AND ACTUATORS

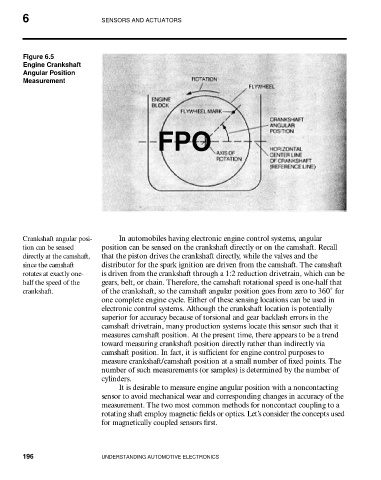

Figure 6.5

Engine Crankshaft

Angular Position

Measurement

FPO

Crankshaft angular posi- In automobiles having electronic engine control systems, angular

tion can be sensed position can be sensed on the crankshaft directly or on the camshaft. Recall

directly at the camshaft, that the piston drives the crankshaft directly, while the valves and the

since the camshaft distributor for the spark ignition are driven from the camshaft. The camshaft

rotates at exactly one- is driven from the crankshaft through a 1:2 reduction drivetrain, which can be

half the speed of the gears, belt, or chain. Therefore, the camshaft rotational speed is one-half that

crankshaft. of the crankshaft, so the camshaft angular position goes from zero to 360˚ for

one complete engine cycle. Either of these sensing locations can be used in

electronic control systems. Although the crankshaft location is potentially

superior for accuracy because of torsional and gear backlash errors in the

camshaft drivetrain, many production systems locate this sensor such that it

measures camshaft position. At the present time, there appears to be a trend

toward measuring crankshaft position directly rather than indirectly via

camshaft position. In fact, it is sufficient for engine control purposes to

measure crankshaft/camshaft position at a small number of fixed points. The

number of such measurements (or samples) is determined by the number of

cylinders.

It is desirable to measure engine angular position with a noncontacting

sensor to avoid mechanical wear and corresponding changes in accuracy of the

measurement. The two most common methods for noncontact coupling to a

rotating shaft employ magnetic fields or optics. Let’s consider the concepts used

for magnetically coupled sensors first.

196 UNDERSTANDING AUTOMOTIVE ELECTRONICS