Page 212 - Understanding Automotive Electronics

P. 212

2735 | CH 6 Page 199 Tuesday, March 10, 1998 1:10 PM

SENSORS AND ACTUATORS 6

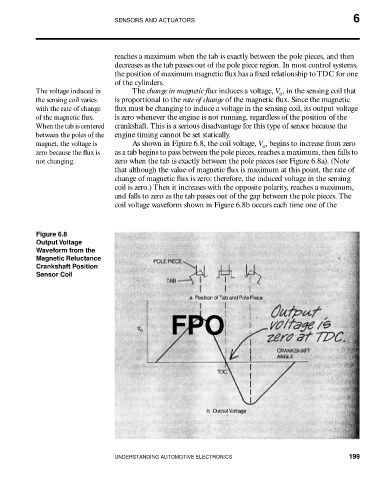

reaches a maximum when the tab is exactly between the pole pieces, and then

decreases as the tab passes out of the pole piece region. In most control systems,

the position of maximum magnetic flux has a fixed relationship to TDC for one

of the cylinders.

The voltage induced in The change in magnetic flux induces a voltage, V , in the sensing coil that

o

the sensing coil varies is proportional to the rate of change of the magnetic flux. Since the magnetic

with the rate of change flux must be changing to induce a voltage in the sensing coil, its output voltage

of the magnetic flux. is zero whenever the engine is not running, regardless of the position of the

When the tab is centered crankshaft. This is a serious disadvantage for this type of sensor because the

between the poles of the engine timing cannot be set statically.

magnet, the voltage is As shown in Figure 6.8, the coil voltage, V , begins to increase from zero

o

zero because the flux is as a tab begins to pass between the pole pieces, reaches a maximum, then falls to

not changing. zero when the tab is exactly between the pole pieces (see Figure 6.8a). (Note

that although the value of magnetic flux is maximum at this point, the rate of

change of magnetic flux is zero; therefore, the induced voltage in the sensing

coil is zero.) Then it increases with the opposite polarity, reaches a maximum,

and falls to zero as the tab passes out of the gap between the pole pieces. The

coil voltage waveform shown in Figure 6.8b occurs each time one of the

Figure 6.8

Output Voltage

Waveform from the

Magnetic Reluctance

Crankshaft Position

Sensor Coil

FPO

UNDERSTANDING AUTOMOTIVE ELECTRONICS 199