Page 180 - Uninterruptible Power Supplies

P. 180

Rotary UPS Systems

178 Chapter Six

D3/1 AUTOM. BY-PASS

A

D1/1 D2/1 Static C/O Critical load 1

CHOKE DIESEL B Switch

ROTARY UPS CLUTCH ENGINE

UPS:1 KS1

Close for

Maintenance

D3/2 AUTOM. BY-PASS

A

D1/2 D2/2 Static C/O Critical load 2

CHOKE DIESEL B Switch

ROTARY UPS CLUTCH ENGINE

UPS:1/2 KS/2

A

Static

D3/3 AUTOM. BY-PASS Switch C/O Critical load 3

B

D1/3 D2/3

CHOKE DIESEL

ROTARY UPS CLUTCH ENGINE

UPS:1/3 KS/3

Close for

Maintenance

D3/4 AUTOM. BY-PASS

A

D1/4 D2/4 Static C/O Critical load 4

CHOKE DIESEL B Switch

ROTARY UPS CLUTCH ENGINE

UPS:1/4 KS/4

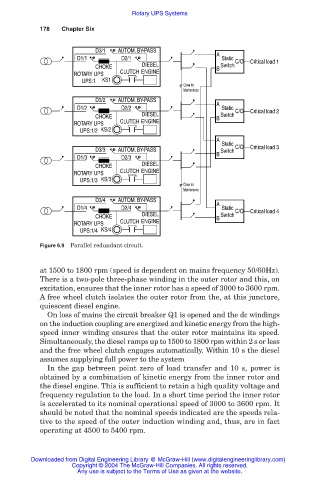

Figure 6.9 Parallel redundant circuit.

at 1500 to 1800 rpm (speed is dependent on mains frequency 50/60Hz).

There is a two-pole three-phase winding in the outer rotor and this, on

excitation, ensures that the inner rotor has a speed of 3000 to 3600 rpm.

A free wheel clutch isolates the outer rotor from the, at this juncture,

quiescent diesel engine.

On loss of mains the circuit breaker Q1 is opened and the dc windings

on the induction coupling are energized and kinetic energy from the high-

speed inner winding ensures that the outer rotor maintains its speed.

Simultaneously, the diesel ramps up to 1500 to 1800 rpm within 2 s or less

and the free wheel clutch engages automatically. Within 10 s the diesel

assumes supplying full power to the system

In the gap between point zero of load transfer and 10 s, power is

obtained by a combination of kinetic energy from the inner rotor and

the diesel engine. This is sufficient to retain a high quality voltage and

frequency regulation to the load. In a short time period the inner rotor

is accelerated to its nominal operational speed of 3000 to 3600 rpm. It

should be noted that the nominal speeds indicated are the speeds rela-

tive to the speed of the outer induction winding and, thus, are in fact

operating at 4500 to 5400 rpm.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.