Page 313 - Water and wastewater engineering

P. 313

7-30 WATER AND WASTEWATER ENGINEERING

of the lime slurry. Flocculation mixing is provided by axial flow impellers or paddle wheels. The

1

flocculation mixing velocity gradient is between 130 and 300 s with a mixing time of 30 to

45 minutes, to achieve Gt values ranging from 200,000 to 400,000. The velocity through ports in

the flocculation basin is in the range 0.15 to 0.36 m/s (Davis and Cornwell, 2008; Horsley et al.,

2005; Kawamura, 2000).

The design process follows that shown in the Chapter 6 examples for vertical turbine and

paddle mixers.

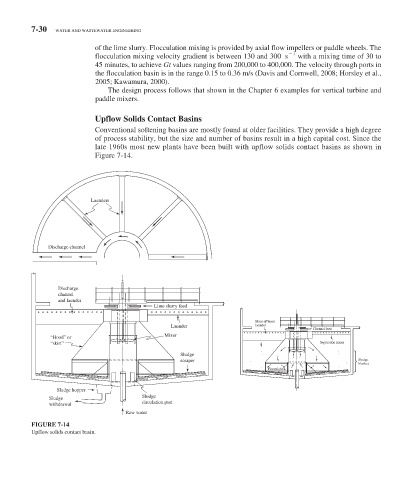

Upflow Solids Contact Basins

Conventional softening basins are mostly found at older facilities. They provide a high degree

of process stability, but the size and number of basins result in a high capital cost. Since the

late 1960s most new plants have been built with upflow solids contact basins as shown in

Figure 7-14 .

Launders

Discharge channel

Discharge

channel

and launder

Lime slurry feed

Mass effluent

Launder launder

Chennal feed

Mixer

“Hood” or

“skirt” Separation zones

Sludge

scraper Sludge

blanket

Flocculation

Sludge hopper

Sludge

Sludge

circulation port

withdrawal

Raw water

FIGURE 7-14

Upflow solids contact basin.