Page 468 - Wind Energy Handbook

P. 468

442 COMPONENT DESIGN

Stator

circuit

Local Wound rotor

transformer Rotor induction

circuit machine

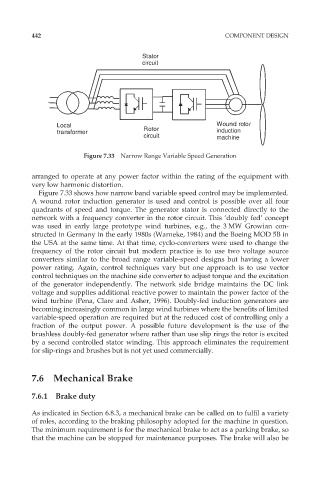

Figure 7.33 Narrow Range Variable Speed Generation

arranged to operate at any power factor within the rating of the equipment with

very low harmonic distortion.

Figure 7.33 shows how narrow band variable speed control may be implemented.

A wound rotor induction generator is used and control is possible over all four

quadrants of speed and torque. The generator stator is connected directly to the

network with a frequency converter in the rotor circuit. This ‘doubly fed’ concept

was used in early large prototype wind turbines, e.g., the 3 MW Growian con-

structed in Germany in the early 1980s (Warneke, 1984) and the Boeing MOD 5B in

the USA at the same time. At that time, cyclo-converters were used to change the

frequency of the rotor circuit but modern practice is to use two voltage source

converters similar to the broad range variable-speed designs but having a lower

power rating. Again, control techniques vary but one approach is to use vector

control techniques on the machine side converter to adjust torque and the excitation

of the generator independently. The network side bridge maintains the DC link

voltage and supplies additional reactive power to maintain the power factor of the

wind turbine (Pena, Clare and Asher, 1996). Doubly-fed induction generators are

becoming increasingly common in large wind turbines where the benefits of limited

variable-speed operation are required but at the reduced cost of controlling only a

fraction of the output power. A possible future development is the use of the

brushless doubly-fed generator where rather than use slip rings the rotor is excited

by a second controlled stator winding. This approach eliminates the requirement

for slip-rings and brushes but is not yet used commercially.

7.6 Mechanical Brake

7.6.1 Brake duty

As indicated in Section 6.8.3, a mechanical brake can be called on to fulfil a variety

of roles, according to the braking philosophy adopted for the machine in question.

The minimum requirement is for the mechanical brake to act as a parking brake, so

that the machine can be stopped for maintenance purposes. The brake will also be