Page 477 - Wind Energy Handbook

P. 477

YAW DRIVE 451

supports the low-speed shaft main bearing at the front and the port and starboard

gearbox supports towards the rear, with the generator mounted on a fabricated

platform projecting to the rear and attached to the main casting by bolts.

Although conventional methods of analysis can be used to design the bedplate

for extreme loads, the complicated shape renders a finite-element analysis essential

for calculating the stress concentration effects needed for fatigue design. Fatigue

analysis is complicated by the need to take into account up to six rotor load

components. However, given stress distributions for each load component obtained

by separate FE analyses, the stress-time history at any point can be obtained by

combining appropriately scaled load component time histories previously obtained

from a load case simulation.

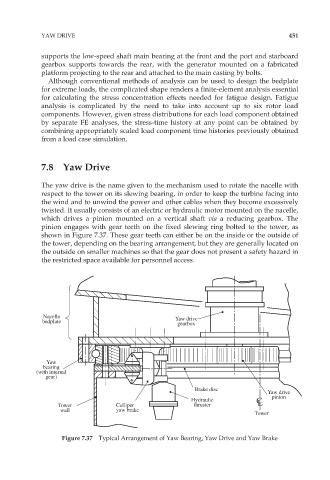

7.8 Yaw Drive

The yaw drive is the name given to the mechanism used to rotate the nacelle with

respect to the tower on its slewing bearing, in order to keep the turbine facing into

the wind and to unwind the power and other cables when they become excessively

twisted. It usually consists of an electric or hydraulic motor mounted on the nacelle,

which drives a pinion mounted on a vertical shaft via a reducing gearbox. The

pinion engages with gear teeth on the fixed slewing ring bolted to the tower, as

shown in Figure 7.37. These gear teeth can either be on the inside or the outside of

the tower, depending on the bearing arrangement, but they are generally located on

the outside on smaller machines so that the gear does not present a safety hazard in

the restricted space available for personnel access.

Nacelle Yaw drive

bedplate gearbox

Yaw

bearing

(with internal

gear)

Brake disc

Yaw drive

pinion

Hydraulic C

Tower Calliper thruster L

wall yaw brake

Tower

Figure 7.37 Typical Arrangement of Yaw Bearing, Yaw Drive and Yaw Brake