Page 475 - Wind Energy Handbook

P. 475

MECHANICAL BRAKE 449

(b) Brake-disc diameter selection: The maximum rotor speed corresponds to a high-

speed shaft speed of 21:9 3 (1500=19) ¼ 1729 r:p:m: ¼ 181 rad=s, so the maxi-

mum permissible brake-disc radius as regards centrifugal stresses is about

90=181 ¼ 0:497 m. It is advisable to choose the largest permitted size in order

to minimize temperature rise, so 1.0 m diameter is selected in this case. The

pad rubbing speed will be quite acceptable if sintered pads are used.

(c) Selection of number and size of brake pads: The total brake-pad area is governed by

the need to keep the maximum power dissipation per unit pad area below

2

11.6 MW/m . The power dissipation is equal to the product of the braking

torque and the rotational speed, so it is at a maximum at the onset of braking,

i.e. 22:8 3 181 ¼ 4128 kW, giving a required total area of the brake pads of

2

4128=11 600 ¼ 0:356 m . This area can be provided by four callipers fitted with

2

0:22 3 0:22 m pads, giving 0.387 m in all.

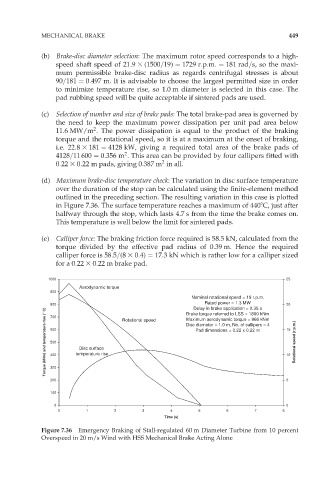

(d) Maximum brake-disc temperature check: The variation in disc surface temperature

over the duration of the stop can be calculated using the finite-element method

outlined in the preceding section. The resulting variation in this case is plotted

in Figure 7.36. The surface temperature reaches a maximum of 4408C, just after

halfway through the stop, which lasts 4.7 s from the time the brake comes on.

This temperature is well below the limit for sintered pads.

(e) Calliper force: The braking friction force required is 58.5 kN, calculated from the

torque divided by the effective pad radius of 0.39 m. Hence the required

calliper force is 58:5=(8 3 0:4) ¼ 17:3 kN which is rather low for a calliper sized

for a 0:22 3 0:22 m brake pad.

1000 25

Aerodynamic torque

900

Nominal rotational speed = 19 r.p.m.

Rated power = 1.3 MW

800 Rotational speed Brake torque referred to LSS = 1800 kNm 20

Delay in brake application = 0.35 s

Torque (kNm) and temperature rise ( C) 600 temperature rise Disc diameter = 1.0 m, No. of callipers = 4 15 Rotational speed (r.p.m.)

700

Maximum aerodynamic torque = 966 kNm

Pad dimensions = 0.22 x 0.22 m

500

Disc surface

10

400

300

200 5

100

0 0

0 1 2 3 4 5 6 7 8

Time (s)

Figure 7.36 Emergency Braking of Stall-regulated 60 m Diameter Turbine from 10 percent

Overspeed in 20 m/s Wind with HSS Mechanical Brake Acting Alone