Page 104 - Wire Bonding in Microelectronics

P. 104

W ir e Bond Testing 83

h (mm)

0 0.1 0.2 0.3 0.4 0.5

14 140

12 120

h (mils)

h (mm)

30

10 100

0.75 20

0.5

Pull force, F, (gf) 8 0.25 80 Pull force (mN)

10

0 (Single level)

60

6

Pull strength (F)

The bond breaks, F, when

4 T (wire tension) = 10 g–f 40

h on the lower bond

2 h h 20

60 mils

1.5 mm

0 0

0 4 8 12 16 20

Height above highest level bond, h (mils)

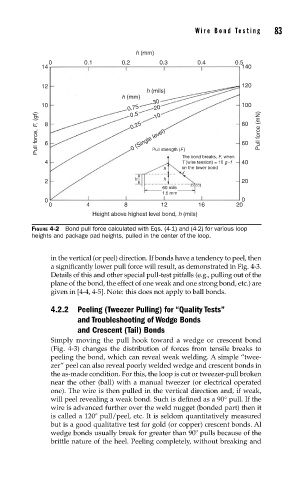

FIGURE 4-2 Bond pull force calculated with Eqs. (4-1) and (4-2) for various loop

heights and package pad heights, pulled in the center of the loop.

in the vertical (or peel) direction. If bonds have a tendency to peel, then

a significantly lower pull force will result, as demonstrated in Fig. 4-3.

Details of this and other special pull-test pitfalls (e.g., pulling out of the

plane of the bond, the effect of one weak and one strong bond, etc.) are

given in [4-4, 4-5]. Note: this does not apply to ball bonds.

4.2.2 Peeling (Tweezer Pulling) for “Quality Tests”

and Troubleshooting of Wedge Bonds

and Crescent (Tail) Bonds

Simply moving the pull hook toward a wedge or crescent bond

(Fig. 4-3) changes the distribution of forces from tensile breaks to

peeling the bond, which can reveal weak welding. A simple “twee-

zer” peel can also reveal poorly welded wedge and crescent bonds in

the as-made condition. For this, the loop is cut or tweezer-pull broken

near the other (ball) with a manual tweezer (or electrical operated

one). The wire is then pulled in the vertical direction and, if weak,

will peel revealing a weak bond. Such is defined as a 90° pull. If the

wire is advanced further over the weld nugget (bonded part) then it

is called a 120º pull/peel, etc. It is seldom quantitatively measured

but is a good qualitative test for gold (or copper) crescent bonds. Al

wedge bonds usually break for greater than 90º pulls because of the

brittle nature of the heel. Peeling completely, without breaking and