Page 102 - Wire Bonding in Microelectronics

P. 102

W ir e Bond Testing 81

making ϕ = 0.] The force in each wire, (f ) and (f ) at wire break, with

wt wd

a specified pull force, F, at the hook is

( h + 2 2 1 /2 − ( (1 )cosφ + ( hH) sin ) φ

+

2

d )

f wt = F d (4-1)

h+ H

22 12

/

+

( 1 + 1 ( Hh ) ( hH ( ) cos φ − sinφ )

d

− )

h

2

d

f wd = F ( + ) + (4-2)

h+ H

If the hook is applied as close as practical to one of the bonds, the

vertical (peel) component of the pull force can approach the force of a

90° pull test (described in MIL STD 883G/H, Method 2011 [4-7] and

illustrated in Fig. 4-3).

When an over-the-ball position of the hook is chosen (to pull ball

bonds vertically), it will break in the HAZ for course pitch. However,

this position is preferred for testing fine pitch ball bonds (not wedges)

to avoid pulling the metallization up (see Chap. 9, fine pitch discus-

sion). These equations can also be used when testing ribbon bonds.

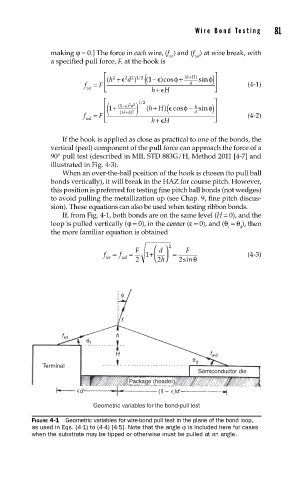

If, from Fig. 4-1, both bonds are on the same level (H = 0), and the

loop is pulled vertically (ϕ = 0), in the center (ε = 0), and (θ = θ ), then

t d

the more familiar equation is obtained

2

f = f = F 1 + d = F (4-3)

wt wd 2 2 h 2sinθ

φ

f

f wt h

θ t

H f wd

θ d

Terminal

Semiconductor die

Package (header)

d (1 – )d

Geometric variables for the bond-pull test

FIGURE 4-1 Geometric variables for wire-bond pull test in the plane of the bond loop,

as used in Eqs. (4-1) to (4-4) [4-5]. Note that the angle ϕ is included here for cases

when the substrate may be tipped or otherwise must be pulled at an angle.