Page 36 - Wire Bonding in Microelectronics

P. 36

Ultrasonic Bonding Systems and Technologies 15

A B

D

C

E

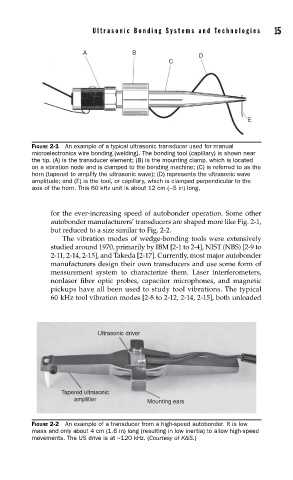

FIGURE 2-1 An example of a typical ultrasonic transducer used for manual

microelectronics wire bonding (welding). The bonding tool (capillary) is shown near

the tip. (A) is the transducer element; (B) is the mounting clamp, which is located

on a vibration node and is clamped to the bonding machine; (C) is referred to as the

horn (tapered to amplify the ultrasonic wave); (D) represents the ultrasonic wave

amplitude; and (E) is the tool, or capillary, which is clamped perpendicular to the

axis of the horn. This 60 kHz unit is about 12 cm (~5 in) long.

for the ever-increasing speed of autobonder operation. Some other

autobonder manufacturers’ transducers are shaped more like Fig. 2-1,

but reduced to a size similar to Fig. 2-2.

The vibration modes of wedge-bonding tools were extensively

studied around 1970, primarily by IBM [2-1 to 2-4], NIST (NBS) [2-9 to

2-11, 2-14, 2-15], and Takeda [2-17]. Currently, most major autobonder

manufacturers design their own transducers and use some form of

measurement system to characterize them. Laser interferometers,

nonlaser fiber optic probes, capacitor microphones, and magnetic

pickups have all been used to study tool vibrations. The typical

60 kHz tool vibration modes [2-8 to 2-12, 2-14, 2-15], both unloaded

Ultrasonic driver

Tapered ultrasonic

amplifier

Mounting ears

FIGURE 2-2 An example of a transducer from a high-speed autobonder. It is low

mass and only about 4 cm (1.6 in) long (resulting in low inertia) to allow high-speed

movements. The US drive is at ~120 kHz. (Courtesy of K&S.)