Page 94 - Wire Bonding in Microelectronics

P. 94

Bonding W ir e Metallur gy and Characteristics 73

category. Whereas, the current carrying capacity of typical PC board

conductors may be large (several amperes), MCM conductors over

thin film dielectrics, may have small cross sections (8 to 25 µm widths

by 4 to 10 µm thickness) and can be embedded in thermally insulating

polyimide, BCB, etc. These can heat up rapidly as the current increases.

However, long before conductor burn-out occurs, the adhesive that

bonds the conductor to a PC board, or the polymer surrounding the

device conductors, may be thermally damaged and cause future reli-

ability problems. Thus, specifications are usually given in terms of

maximum permissible temperature rise rather than maximum current.

The current capacity of vias and other constrictions must also be con-

sidered, as well as solder joints which could melt. Under worse condi-

tions, the PC board or SIP insulating material could burst into flames.

There have been many studies of the safe current carrying capacities of

PC boards. See, for example, Refs. [3-36 to 3-38].

A concise summary of Cu wire advantages and problems was

given in a technical publication by Coors/Gaiser/Tool. It is included

as App. 3B. Many studies are going on to implement 1.0 mil or less

diameter wire.

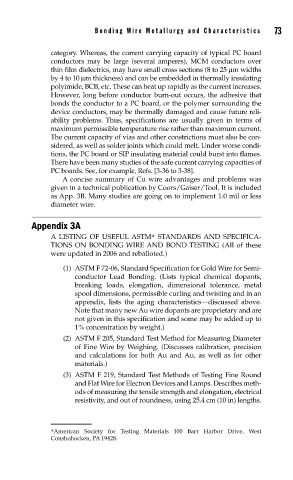

Appendix 3A

A LISTING OF USEFUL ASTM∗ STANDARDS AND SPECIFICA-

TIONS ON BONDING WIRE AND BOND TESTING (All of these

were updated in 2006 and reballoted.)

(1) ASTM F 72-06, Standard Specification for Gold Wire for Semi-

conductor Lead Bonding. (Lists typical chemical dopants,

breaking loads, elongation, dimensional tolerance, metal

spool dimensions, permissible curling and twisting and in an

appendix, lists the aging characteristics—discussed above.

Note that many new Au wire dopants are proprietary and are

not given in this specification and some may be added up to

1% concentration by weight.)

(2) ASTM F 205, Standard Test Method for Measuring Diameter

of Fine Wire by Weighing. (Discusses calibration, precision

and calculations for both Au and Au, as well as for other

materials.)

(3) ASTM F 219, Standard Test Methods of Testing Fine Round

and Flat Wire for Electron Devices and Lamps. Describes meth-

ods of measuring the tensile strength and elongation, electrical

resistivity, and out of roundness, using 25.4 cm (10 in) lengths.

∗American Society for Testing Materials 100 Barr Harbor Drive, West

Conshohocken, PA 19428.