Page 95 - Wire Bonding in Microelectronics

P. 95

74 Cha pte r T h ree

(4) ASTM F 487-06, Standard Specification for Fine Aluminum-

1% Silicon Wire for Semiconductor Lead Bonding. (Most of

the same information as in F 72 above but for Al, 1% Si wire.)

(5) ASTM F 584-06, Standard Practice for Visual Inspection of

Semiconductor Lead-Bonding Wire. (This may be discontinued

but is useful as it gives manual procedures and photographs

of acceptable and unacceptably cleaned bonding wires.)

Appendix 3B

Copper Wire Bonding, a Low-Cost Solution to Gold Wire Bonding?

From Industry Newsletter & Technical Publication, Volume III,

Issue 4, July 2005. (Used with Permission of COORS TEK/GAISER

precision bonding tools.)

Introduction: Part one of this discussion covered aspects of the

ball formation; the various ways to achieve size and shape consis-

tency. In this section, the material properties in particular the hard-

ness and the impact on ball bonding will be discussed. The copper

bonding process is not simply about how to make a good free-air

ball but how to achieve good product quality and reliability.

The Facts:

Copper is a good electrical and thermal conductor, better than

gold (see Table 3B-1).

Copper wire is harder than gold (see Table 3B -1).

Copper as a raw material is cheaper and more abundant than gold

(>$0.20/oz. vs. >$800/oz).

Copper oxidizes easily, gold does not.

Copper wire bonding uses a limited number of specially designed

capillaries, gold wire does not.

Copper processing requires special hardware to prevent oxidation,

gold does not.

Copper when bonded to Aluminum pads forms thin inter-

metallic layers, Gold forms thick intermetallic layers (see gold

in Fig. 3B-1).

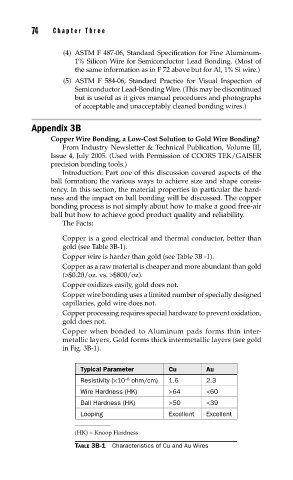

Typical Parameter Cu Au

−6

Resistivity (×10 ohm/cm) 1.6 2.3

Wire Hardness (HK) >64 <60

Ball Hardness (HK) >50 <39

Looping Excellent Excellent

(HK) = Knoop Hardness

TABLE 3B-1 Characteristics of Cu and Au Wires