Page 182 - Mechanical Behavior of Materials

P. 182

Problems and Questions 183

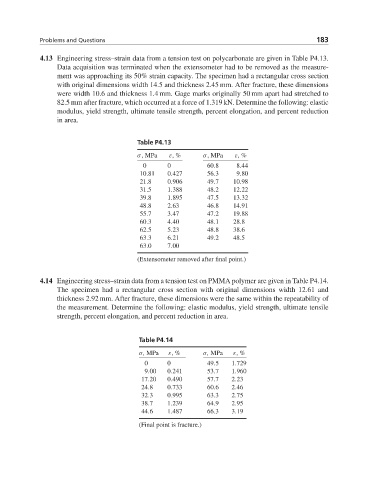

4.13 Engineering stress–strain data from a tension test on polycarbonate are given in Table P4.13.

Data acquisition was terminated when the extensometer had to be removed as the measure-

ment was approaching its 50% strain capacity. The specimen had a rectangular cross section

with original dimensions width 14.5 and thickness 2.45 mm. After fracture, these dimensions

were width 10.6 and thickness 1.4 mm. Gage marks originally 50 mm apart had stretched to

82.5 mm after fracture, which occurred at a force of 1.319 kN. Determine the following: elastic

modulus, yield strength, ultimate tensile strength, percent elongation, and percent reduction

in area.

Table P4.13

σ,MPa ε,% σ,MPa ε,%

0 0 60.8 8.44

10.81 0.427 56.3 9.80

21.8 0.906 49.7 10.98

31.5 1.388 48.2 12.22

39.8 1.895 47.5 13.32

48.8 2.63 46.8 14.91

55.7 3.47 47.2 19.88

60.3 4.40 48.1 28.8

62.5 5.23 48.8 38.6

63.3 6.21 49.2 48.5

63.0 7.00

(Extensometer removed after final point.)

4.14 Engineering stress–strain data from a tension test on PMMA polymer are given in Table P4.14.

The specimen had a rectangular cross section with original dimensions width 12.61 and

thickness 2.92 mm. After fracture, these dimensions were the same within the repeatability of

the measurement. Determine the following: elastic modulus, yield strength, ultimate tensile

strength, percent elongation, and percent reduction in area.

Table P4.14

σ, MPa ε,% σ, MPa ε,%

0 0 49.5 1.729

9.00 0.241 53.7 1.960

17.20 0.490 57.7 2.23

24.8 0.733 60.6 2.46

32.3 0.995 63.3 2.75

38.7 1.239 64.9 2.95

44.6 1.487 66.3 3.19

(Final point is fracture.)