Page 282 - Adsorbents fundamentals and applications

P. 282

POLYMERIC RESINS 267

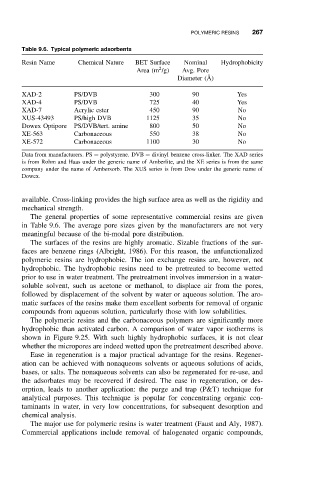

Table 9.6. Typical polymeric adsorbents

Resin Name Chemical Nature BET Surface Nominal Hydrophobicity

2

Area (m /g) Avg. Pore

Diameter ( ˚ A)

XAD-2 PS/DVB 300 90 Yes

XAD-4 PS/DVB 725 40 Yes

XAD-7 Acrylic ester 450 90 No

XUS-43493 PS/high DVB 1125 35 No

Dowex Optipore PS/DVB/tert. amine 800 50 No

XE-563 Carbonaceous 550 38 No

XE-572 Carbonaceous 1100 30 No

Data from manufacturers. PS = polystyrene. DVB = divinyl benzene cross-linker. The XAD series

is from Rohm and Haas under the generic name of Amberlite, and the XE series is from the same

company under the name of Ambersorb. The XUS series is from Dow under the generic name of

Dowex.

available. Cross-linking provides the high surface area as well as the rigidity and

mechanical strength.

The general properties of some representative commercial resins are given

in Table 9.6. The average pore sizes given by the manufacturers are not very

meaningful because of the bi-modal pore distribution.

The surfaces of the resins are highly aromatic. Sizable fractions of the sur-

faces are benzene rings (Albright, 1986). For this reason, the unfunctionalized

polymeric resins are hydrophobic. The ion exchange resins are, however, not

hydrophobic. The hydrophobic resins need to be pretreated to become wetted

prior to use in water treatment. The pretreatment involves immersion in a water-

soluble solvent, such as acetone or methanol, to displace air from the pores,

followed by displacement of the solvent by water or aqueous solution. The aro-

matic surfaces of the resins make them excellent sorbents for removal of organic

compounds from aqueous solution, particularly those with low solubilities.

The polymeric resins and the carbonaceous polymers are significantly more

hydrophobic than activated carbon. A comparison of water vapor isotherms is

shown in Figure 9.25. With such highly hydrophobic surfaces, it is not clear

whether the micropores are indeed wetted upon the pretreatment described above.

Ease in regeneration is a major practical advantage for the resins. Regener-

ation can be achieved with nonaqueous solvents or aqueous solutions of acids,

bases, or salts. The nonaqueous solvents can also be regenerated for re-use, and

the adsorbates may be recovered if desired. The ease in regeneration, or des-

orption, leads to another application: the purge and trap (P&T) technique for

analytical purposes. This technique is popular for concentrating organic con-

taminants in water, in very low concentrations, for subsequent desorption and

chemical analysis.

The major use for polymeric resins is water treatment (Faust and Aly, 1987).

Commercial applications include removal of halogenated organic compounds,