Page 347 - Adsorbents fundamentals and applications

P. 347

332 SORBENTS FOR APPLICATIONS

simulation results for an olefin-leaner feed composed of 50% C 3 H 6 and 50%

C 3 H 8 at the same temperature are shown in Table 10.10. The first two runs

under each sorbent heading show the PSA performance at a desorption pressure

of 1.0 atm. The next two runs were conducted at a lower desorption pressure

of 0.2 atm.

A comparison of runs 2 and 6 in Table 10.9 for a feed of 85% C 3 H 6 and 15%

C 3 H 8 shows that for a nearly similar product purity (99.2%) and product recovery

(60–65%), the product throughput of the AgNO /SiO 2 sorbent exceeded that of

3

AlPO 4 -14 by over 70%. Similarly, for the lower desorption pressure of 0.2 atm,

an inspection of runs 4 and 8 shows that at a product purity of about 99.2%, both

the product recovery as well as the product throughput for the AgNO /SiO 2

3

sorbent are higher than those shown by the AlPO 4 -14 sorbent. Thus clearly,

AgNO /SiO 2 is a better sorbent for a hydrocarbon feed, which is richer in olefin

3

compared with paraffin. This fact holds true irrespective of the operating pressure

range of the PSA process.

The results of the PSA performance for a more olefin-lean feed of 50% C 3 H 6

and 50% C 3 H 8 can be obtained from Table 10.10. The comparison for this feed

was less straightforward than that in Table 10.9. In general, it was difficult to

exceed 99% purity in the case of AlPO 4 -14 at reasonable product recovery and

throughput. From runs 9 and 14, it can be seen that for a product purity in the

range of 98–99%, the product recovery and product throughput were nearly the

same (46% and 2 × 10 −3 kg product/kg sorbent/h, respectively). However for

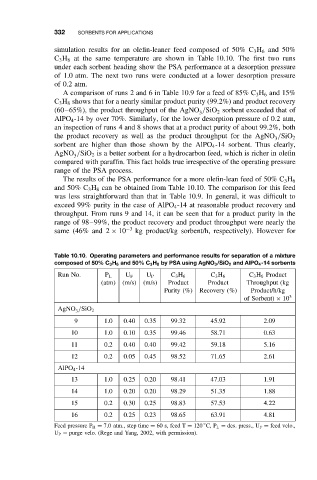

Table 10.10. Operating parameters and performance results for separation of a mixture

composed of 50% C 3 H 6 and 50% C 3 H 8 by PSA using AgNO 3 /SiO 2 and AlPO 4 -14 sorbents

Run No. P L U F U P C 3 H 6 C 3 H 6 C 3 H 6 Product

(atm) (m/s) (m/s) Product Product Throughput (kg

Purity (%) Recovery (%) Product/h/kg

of Sorbent) × 10 3

AgNO /SiO 2

3

9 1.0 0.40 0.35 99.32 45.92 2.09

10 1.0 0.10 0.35 99.46 58.71 0.63

11 0.2 0.40 0.40 99.42 59.18 5.16

12 0.2 0.05 0.45 98.52 71.65 2.61

AlPO 4 -14

13 1.0 0.25 0.20 98.41 47.03 1.91

14 1.0 0.20 0.20 98.29 51.35 1.88

15 0.2 0.30 0.25 98.83 57.53 4.22

16 0.2 0.25 0.23 98.65 63.91 4.81

◦

Feed pressure P H = 7.0 atm., step time = 60 s, feed T = 120 C, P L = des. press., U F = feed velo.,

U P = purge velo. (Rege and Yang, 2002, with permission).