Page 65 - An Introduction to Microelectromechanical Systems Engineering

P. 65

44 Processes for Micromachining

Mask alignment keys Front side Microscope view

Mask

Wafer

Chuck

Wafer alignment keys

Microscope

(a) objectives

(b)

Y

X

(c)

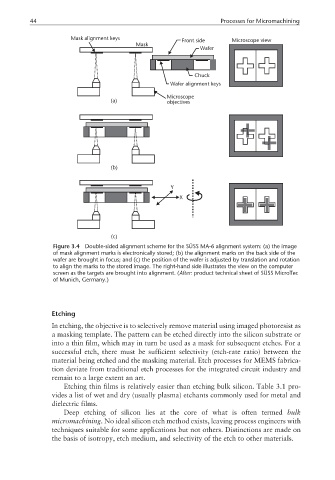

Figure 3.4 Double-sided alignment scheme for the SÜSS MA-6 alignment system: (a) the image

of mask alignment marks is electronically stored; (b) the alignment marks on the back side of the

wafer are brought in focus; and (c) the position of the wafer is adjusted by translation and rotation

to align the marks to the stored image. The right-hand side illustrates the view on the computer

screen as the targets are brought into alignment. (After: product technical sheet of SÜSS MicroTec

of Munich, Germany.)

Etching

In etching, the objective is to selectively remove material using imaged photoresist as

a masking template. The pattern can be etched directly into the silicon substrate or

into a thin film, which may in turn be used as a mask for subsequent etches. For a

successful etch, there must be sufficient selectivity (etch-rate ratio) between the

material being etched and the masking material. Etch processes for MEMS fabrica-

tion deviate from traditional etch processes for the integrated circuit industry and

remain to a large extent an art.

Etching thin films is relatively easier than etching bulk silicon. Table 3.1 pro-

vides a list of wet and dry (usually plasma) etchants commonly used for metal and

dielectric films.

Deep etching of silicon lies at the core of what is often termed bulk

micromachining. No ideal silicon etch method exists, leaving process engineers with

techniques suitable for some applications but not others. Distinctions are made on

the basis of isotropy, etch medium, and selectivity of the etch to other materials.