Page 70 - An Introduction to Microelectromechanical Systems Engineering

P. 70

Basic Process Tools 49

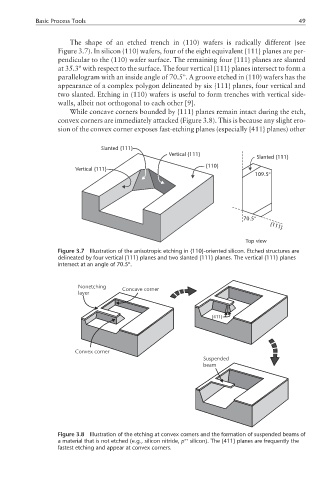

The shape of an etched trench in (110) wafers is radically different (see

Figure 3.7). In silicon (110) wafers, four of the eight equivalent {111} planes are per-

pendicular to the (110) wafer surface. The remaining four {111} planes are slanted

at 35.3º with respect to the surface. The four vertical {111} planes intersect to form a

parallelogram with an inside angle of 70.5º. A groove etched in (110) wafers has the

appearance of a complex polygon delineated by six {111} planes, four vertical and

two slanted. Etching in (110) wafers is useful to form trenches with vertical side-

walls, albeit not orthogonal to each other [9].

While concave corners bounded by {111} planes remain intact during the etch,

convex corners are immediately attacked (Figure 3.8). This is because any slight ero-

sion of the convex corner exposes fast-etching planes (especially {411} planes) other

Slanted {111}

Vertical {111}

Slanted {111}

{110}

Vertical {111}

109.5°

70.5° {111}

Top view

Figure 3.7 Illustration of the anisotropic etching in {110}-oriented silicon. Etched structures are

delineated by four vertical {111} planes and two slanted {111} planes. The vertical {111} planes

intersect at an angle of 70.5º.

Nonetching

Concave corner

layer

{411}

Convex corner

Suspended

beam

Figure 3.8 Illustration of the etching at convex corners and the formation of suspended beams of

++

a material that is not etched (e.g., silicon nitride, p silicon). The {411} planes are frequently the

fastest etching and appear at convex corners.