Page 74 - An Introduction to Microelectromechanical Systems Engineering

P. 74

Basic Process Tools 53

Mask

F

+

SF x

Etch

Silicon

+

nCF x

Deposit polymer

Polymer (nCF )

2

F

+

SF x

Etch

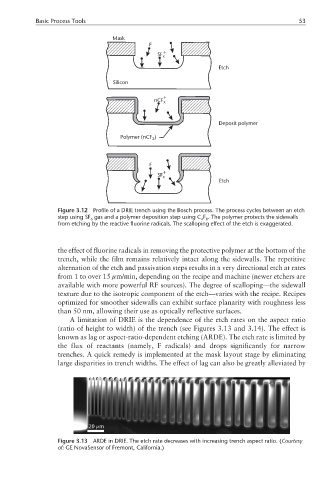

Figure 3.12 Profile of a DRIE trench using the Bosch process. The process cycles between an etch

step using SF gas and a polymer deposition step using C F . The polymer protects the sidewalls

6 4 8

from etching by the reactive fluorine radicals. The scalloping effect of the etch is exaggerated.

the effect of fluorine radicals in removing the protective polymer at the bottom of the

trench, while the film remains relatively intact along the sidewalls. The repetitive

alternation of the etch and passivation steps results in a very directional etch at rates

from 1 to over 15 µm/min, depending on the recipe and machine (newer etchers are

available with more powerful RF sources). The degree of scalloping—the sidewall

texture due to the isotropic component of the etch—varies with the recipe. Recipes

optimized for smoother sidewalls can exhibit surface planarity with roughness less

than 50 nm, allowing their use as optically reflective surfaces.

A limitation of DRIE is the dependence of the etch rates on the aspect ratio

(ratio of height to width) of the trench (see Figures 3.13 and 3.14). The effect is

known as lag or aspect-ratio-dependent etching (ARDE). The etch rate is limited by

the flux of reactants (namely, F radicals) and drops significantly for narrow

trenches. A quick remedy is implemented at the mask layout stage by eliminating

large disparities in trench widths. The effect of lag can also be greatly alleviated by

µ

20 m

Figure 3.13 ARDE in DRIE. The etch rate decreases with increasing trench aspect ratio. (Courtesy

of: GE NovaSensor of Fremont, California.)