Page 68 - An Introduction to Microelectromechanical Systems Engineering

P. 68

Basic Process Tools 47

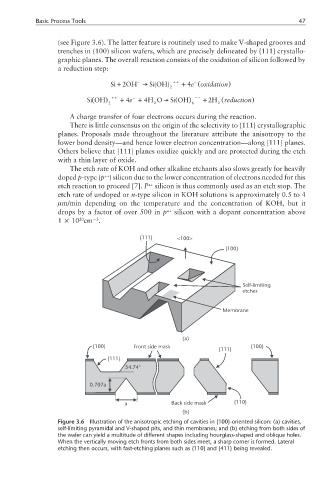

(see Figure 3.6). The latter feature is routinely used to make V-shaped grooves and

trenches in (100) silicon wafers, which are precisely delineated by {111} crystallo-

graphic planes. The overall reaction consists of the oxidation of silicon followed by

a reduction step:

−

(

Si+2 OH → Si OH) 2 ++ +4e − (oxidation )

Si (OH ) ++ + 4e − + 4 H O→ Si (OH ) −− + 2 H (reduction )

2 2 6 2

A charge transfer of four electrons occurs during the reaction.

There is little consensus on the origin of the selectivity to {111} crystallographic

planes. Proposals made throughout the literature attribute the anisotropy to the

lower bond density—and hence lower electron concentration—along {111} planes.

Others believe that {111} planes oxidize quickly and are protected during the etch

with a thin layer of oxide.

The etch rate of KOH and other alkaline etchants also slows greatly for heavily

++

doped p-type (p ) silicon due to the lower concentration of electrons needed for this

etch reaction to proceed [7]. P silicon is thus commonly used as an etch stop. The

++

etch rate of undoped or n-type silicon in KOH solutions is approximately 0.5 to 4

µm/min depending on the temperature and the concentration of KOH, but it

drops by a factor of over 500 in p ++ silicon with a dopant concentration above

−3

1 × 10 cm .

20

{111} <100>

{100}

Self-limiting

etches

Membrane

(a)

{100} Front side mask {100}

{111}

{111}

54.74°

0.707a

a Back side mask {110}

(b)

Figure 3.6 Illustration of the anisotropic etching of cavities in {100}-oriented silicon: (a) cavities,

self-limiting pyramidal and V-shaped pits, and thin membranes; and (b) etching from both sides of

the wafer can yield a multitude of different shapes including hourglass-shaped and oblique holes.

When the vertically moving etch fronts from both sides meet, a sharp corner is formed. Lateral

etching then occurs, with fast-etching planes such as {110} and {411} being revealed.