Page 67 - An Introduction to Microelectromechanical Systems Engineering

P. 67

46 Processes for Micromachining

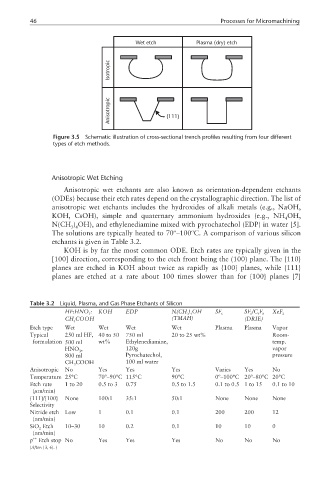

Wet etch Plasma (dry) etch

Isotropic

Anisotropic {111}

Figure 3.5 Schematic illustration of cross-sectional trench profiles resulting from four different

types of etch methods.

Anisotropic Wet Etching

Anisotropic wet etchants are also known as orientation-dependent etchants

(ODEs) because their etch rates depend on the crystallographic direction. The list of

anisotropic wet etchants includes the hydroxides of alkali metals (e.g., NaOH,

KOH, CsOH), simple and quaternary ammonium hydroxides (e.g., NH OH,

4

N(CH ) OH), and ethylenediamine mixed with pyrochatechol (EDP) in water [5].

3 4

The solutions are typically heated to 70º–100ºC. A comparison of various silicon

etchants is given in Table 3.2.

KOH is by far the most common ODE. Etch rates are typically given in the

[100] direction, corresponding to the etch front being the (100) plane. The {110}

planes are etched in KOH about twice as rapidly as {100} planes, while {111}

planes are etched at a rate about 100 times slower than for {100} planes [7]

Table 3.2 Liquid, Plasma, and Gas Phase Etchants of Silicon

HF:HNO : KOH EDP N(CH ) OH SF SF /C F XeF

3 3 4 6 6 4 8 2

CH COOH (TMAH) (DRIE)

3

Etch type Wet Wet Wet Wet Plasma Plasma Vapor

Typical 250 ml HF, 40 to 50 750 ml 20 to 25 wt% Room-

formulation 500 ml wt% Ethylenediamine, temp.

HNO , 120g vapor

3

800 ml Pyrochatechol, pressure

CH COOH 100 ml water

3

Anisotropic No Yes Yes Yes Varies Yes No

Temperature 25°C 70º–90°C 115°C 90°C 0º–100°C 20º–80°C 20°C

Etch rate 1 to 20 0.5 to 3 0.75 0.5 to 1.5 0.1 to 0.5 1 to 15 0.1 to 10

(µm/min)

{111}/{100} None 100:1 35:1 50:1 None None None

Selectivity

Nitride etch Low 1 0.1 0.1 200 200 12

(nm/min)

SiO Etch 10–30 10 0.2 0.1 10 10 0

2

(nm/min)

++

p Etch stop No Yes Yes Yes No No No

(After: [3, 6]. )