Page 115 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 115

66131_Ludwig_CH10C 5/30/2001 4:21 PM Page 82

82 Applied Process Design for Chemical and Petrochemical Plants

Table 10-13

Suggested Fouling Factors in Petrochemical Processes

2

r (hr) (ft ) (°F)/Btu

Temperature Range

Fluid Velocity, Ft/Sec 100°F 100°F

Waters:

Sea (limited to 125°F max.) 4 0.002 0.003

7 0.0015 0.002

River (settled) 2 0.002 0.002—0.003

4 0.0005—0.0015 0.001—0.0025

River (treated and settled) 2 0.0015 0.002

4 0.001 0.0015

4 mils baked phenolic coating 65 0.0005 Fouling Factor, hr-ft 2 -°F/Btu Fouling Factor

15 mils vinyl-aluminum coating 0.001

Condensate (100°—300°F) 2 0.001 0.002—0.0004

4 0.0005 0.001

Steam (saturated) oil free 0.0005—0.0015

with traces oil 0.001—0.002

ethylene, propylene, butane-clean) }

Light hydrocarbon liquids

(methane, ethane, propane,

Light hydrocarbon vapors: (clean) 0.001

Chlorinated hydrocarbons

(carbon tetrachloride,

chloroform, ethylene dichloride,

etc.)

Liquid 0.001 0.002

Condensing 0.001 0.0015

Boiling 0.002 0.002

Refrigerants (vapor condensing

and liquid cooling)

Ammonia 0.001

Propylene 0.001

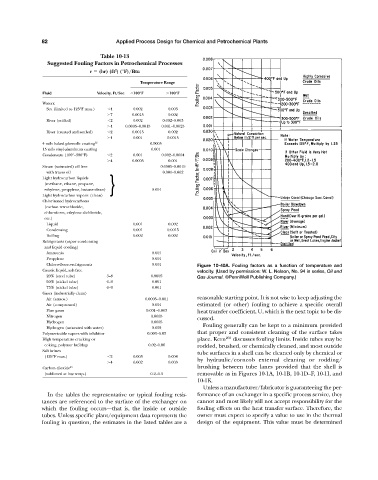

Chloro-fluoro-refrigerants 0.001 Figure 10-40A. Fouling factors as a function of temperature and

Caustic liquid, salt-free velocity. (Used by permission: W. L. Nelson, No. 94 in series, Oil and

20% (steel tube) 3—8 0.0005 Gas Journal. ©PennWell Publishing Company.)

50% (nickel tube) 6—9 0.001

73% (nickel tube) 6—9 0.001

Gases (industrially clean)

Air (atmos.) 0.0005—0.001 reasonable starting point. It is not wise to keep adjusting the

Air (compressed) 0.001 estimated (or other) fouling to achieve a specific overall

Flue gases 0.001—0.003 heat transfer coefficient, U, which is the next topic to be dis-

Nitrogen 0.0005

cussed.

Hydrogen 0.0005

Fouling generally can be kept to a minimum provided

Hydrogen (saturated with water) 0.002

Polymerizable vapors with inhibitor 0.003—0.03 that proper and consistent cleaning of the surface takes

High temperature cracking or place. Kern 269 discusses fouling limits. Inside tubes may be

coking, polymer buildup 0.02—0.06 rodded, brushed, or chemically cleaned, and most outside

Salt brines

tube surfaces in a shell can be cleaned only by chemical or

(125°F max.) 2 0.003 0.004

by hydraulic/corncob external cleaning or rodding/

4 0.002 0.003

Carbon dioxide 93 brushing between tube lanes provided that the shell is

(sublimed at low temp.) 0.2—0.3 removable as in Figures 10-1A, 10-1B, 10-1D—F, 10-1I, and

10-1K.

Unless a manufacturer/fabricator is guaranteeing the per-

In the tables the representative or typical fouling resis- formance of an exchanger in a specific process service, they

tances are referenced to the surface of the exchanger on cannot and most likely will not accept responsibility for the

which the fouling occurs—that is, the inside or outside fouling effects on the heat transfer surface. Therefore, the

tubes. Unless specific plant/equipment data represents the owner must expect to specify a value to use in the thermal

fouling in question, the estimates in the listed tables are a design of the equipment. This value must be determined