Page 73 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 73

62 Applied Process Design for Chemical and Petrochemical Plants

Xylene: Sensible heat Example 8-20: Open Steam Stripping of Heavy Absorber

(106) (33.33) [0.40 x 1.81 (80”-20”) = 153,000 Rich Oil of Light Hydrocarbon Content (used by

Latent heat permission following the method of R W. Ellerbee,

(106) (33.33) (82.87 x 1.8) = 525,000 ChensiCaZ Engineering [ 1271)

Total heat load 1,872,400 Btu A gas processing plant selectively extracts ethylene and

1,872,400 Btu / 100 mols I ethane from an incoming natural gas mixture stream.

Lbs steam required for heat load =

970 Btu/lb at 212°F These two light hydrocarbons are absorbed in a heavy gas*

line type absorber “oil,” and then stripped with open steam

= 1,932 lbs steam/lOO mols in an open tower. The system data are (see Figure 841):

volatile

Rich oil rate to tower: 8,500 mol/hr

1,932

Mols steam required for heat load = - Overhead product of ethylene and ethane: 775 mol/hr

18 Overhead product from

= 107.2 mols steam / 100 mols volatile material accumulator: 55% vapor and 45% liquid

Accumulator conditions: 48 psia and 133.F

Reflux hydrocarbon in top vapor @ 175°F: 850 mol/hr

Total mols steam/lOO mols volatile feed = 153.7 + 107.2 Steam (superheated) enter bottoms

= 262.9 below tray: 14,000 lb/hr

Water partial pressure in the mixed vapor

Total pressure of system: at bottoms: 20 psi

Hydrocarbons mix partial pressure: 50 psi - 20 psi = 30 psi

Ng + LOT

n=

Ii/pi Neglect pressure drops through the system.

igs Determine: How much water is removed from the over-

LT = Total mols volatile material at start = 100 head accumulator and the intermediate dehydrator or

water removal tray? No water is removed from the bottoms

x= 155*7 ’ loo = 580 mm Hg abs due to the use of superheated steam.

0.4397

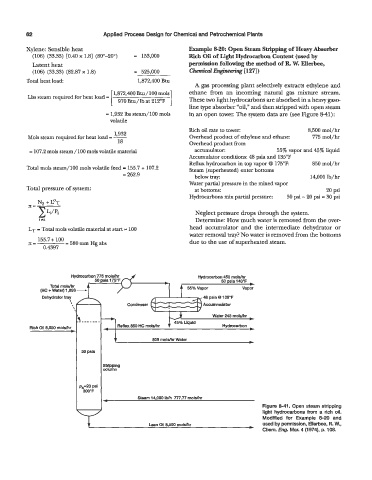

Hydrocarbon 775 rnolslhr Hydrocarbon 450 rnolslhr

50 Dsia 140°F

Total rnolalhr 48 psia 8 135°F vapr

- Condenser Accurnmulator

(HC + Water) 1,893

Dehydrator tray

\

Water 243 molslhr

-

Rich Oil 8 500 rnolalhr ! - - - - - . Reflux 850 HC rnolslhr 45% Liquid Hydrocarbon

509 rnolshr Water

L-

50 psia

Stripping

solurnn

p,=20 psi

300°F

Steam 14,000 Ib/h 777.77 mols/hr

4 Figure 6-41. Open steam stripping

+ light hydrocarbons from a rich oil.

Modified for ExarnDle 8-20 and

Lean Oil 8,500 rnolslhr

L- used by permission, Ellerbee, R. W.,

Chem. Eng. Mar. 4 (1974), p. 108.