Page 214 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 214

CH AP TER 8 .1 Types of suspension and drive

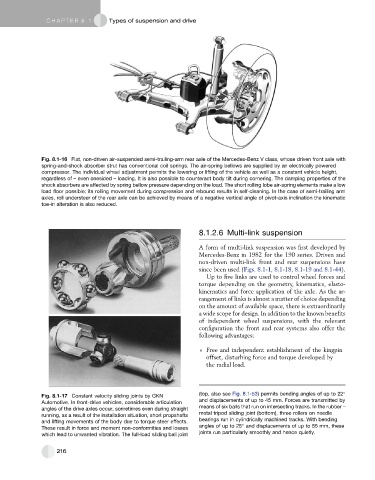

Fig. 8.1-16 Flat, non-driven air-suspended semi-trailing-arm rear axle of the Mercedes-Benz V class, whose driven front axle with

spring-and-shock absorber strut has conventional coil springs. The air-spring bellows are supplied by an electrically powered

compressor. The individual wheel adjustment permits the lowering or lifting of the vehicle as well as a constant vehicle height,

regardless of – even onesided – loading. It is also possible to counteract body tilt during cornering. The damping properties of the

shock absorbers are affected by spring bellow pressure depending on the load. The short rolling lobe air-spring elements make a low

load floor possible; its rolling movement during compression and rebound results in self-cleaning. In the case of semi-trailing arm

axles, roll understeer of the rear axle can be achieved by means of a negative vertical angle of pivot-axis inclination the kinematic

toe-in alteration is also reduced.

8.1.2.6 Multi-link suspension

A form of multi-link suspension was first developed by

Mercedes-Benz in 1982 for the 190 series. Driven and

non-driven multi-link front and rear suspensions have

since been used (Figs. 8.1-1, 8.1-18, 8.1-19 and 8.1-44).

Up to five links are used to control wheel forces and

torque depending on the geometry, kinematics, elasto-

kinematics and force application of the axle. As the ar-

rangement of links is almost a matter of choice depending

on the amount of available space, there is extraordinarily

a wide scope for design. In addition to the known benefits

of independent wheel suspensions, with the relevant

configuration the front and rear systems also offer the

following advantages:

Free and independent establishment of the kingpin

offset, disturbing force and torque developed by

the radial load.

(top, also see Fig. 8.1-53) permits bending angles of up to 22

Fig. 8.1-17 Constant velocity sliding joints by GKN

Automotive. In front-drive vehicles, considerable articulation and displacements of up to 45 mm. Forces are transmitted by

means of six balls that run on intersecting tracks. In the rubber –

angles of the drive axles occur, sometimes even during straight

running, as a result of the installation situation, short propshafts metal tripod sliding joint (bottom), three rollers on needle

bearings run in cylindrically machined tracks. With bending

and lifting movements of the body due to torque steer effects.

These result in force and moment non-conformities and losses angles of up to 25 and displacements of up to 55 mm, these

which lead to unwanted vibration. The full-load sliding ball joint joints run particularly smoothly and hence quietly.

216