Page 268 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 268

CH AP TER 9 .1 Steering

arrangement, about 650 kg and 6000 N, 850 kg and 8000 steering-wheel torque and driving speed signals and the

N or 1300 kg and 10 000 N. servomotor 5 controlled accordingly.

The systems only have limited power because the

current is limited by an operating voltage of 12 V. They

are of interest though for smaller vehicles. In this class of 9.1.5 Steering column

vehicles in particular, electric power steering systems

show their advantages, not least because of the small In accordance with the German standard DIN 70 023

amount of energy required. The introduction of the in- ‘nomenclature of vehicle components’, the steering

creased voltage of 42 V will make the use of electrical column consists of the jacket tube (also known as the

power steering systems and wheel brakes much easier. outer tube or protective sleeve), which is fixed to the

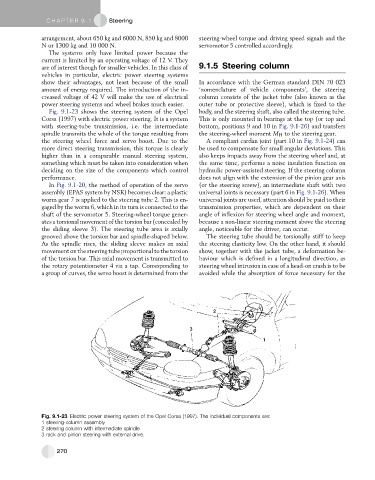

Fig. 9.1-23 shows the steering system of the Opel body, and the steering shaft, also called the steering tube.

Corsa (1997) with electric power steering. It is a system This is only mounted in bearings at the top (or top and

with steering-tube transmission, i.e. the intermediate bottom, positions 9 and 10 in Fig. 9.1-26) and transfers

spindle transmits the whole of the torque resulting from the steering-wheel moment M H to the steering gear.

the steering wheel force and servo boost. Due to the A compliant cardan joint (part 10 in Fig. 9.1-24) can

more direct steering transmission, this torque is clearly be used to compensate for small angular deviations. This

higher than in a comparable manual steering system, also keeps impacts away from the steering wheel and, at

something which must be taken into consideration when the same time, performs a noise insulation function on

deciding on the size of the components which control hydraulic power-assisted steering. If the steering column

performance. does not align with the extension of the pinion gear axis

In Fig. 9.1-20, the method of operation of the servo (or the steering screw), an intermediate shaft with two

assembly (EPAS system by NSK) becomes clear: a plastic universal joints is necessary (part 6 in Fig. 9.1-26). When

worm gear 7 is applied to the steering tube 2. This is en- universal joints are used, attention should be paid to their

gaged by the worm 6, which in its turn is connected to the transmission properties, which are dependent on their

shaft of the servomotor 5. Steering-wheel torque gener- angle of inflexion for steering wheel angle and moment,

ates a torsional movement of the torsion bar (concealed by because a non-linear steering moment above the steering

the sliding sleeve 3). The steering tube area is axially angle, noticeable for the driver, can occur.

grooved above the torsion bar and spindle-shaped below. The steering tube should be torsionally stiff to keep

As the spindle rises, the sliding sleeve makes an axial the steering elasticity low. On the other hand, it should

movement on the steering tube proportional to the torsion show, together with the jacket tube, a deformation be-

of the torsion bar. This axial movement is transmitted to haviour which is defined in a longitudinal direction, as

the rotary potentiometer 4 via a tap. Corresponding to steering wheel intrusion in case of a head-on crash is to be

a group of curves, the servo boost is determined from the avoided while the absorption of force necessary for the

Fig. 9.1-23 Electric power steering system of the Opel Corsa (1997). The individual components are:

1 steering-column assembly

2 steering column with intermediate spindle

3 rack and pinion steering with external drive.

270