Page 399 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 399

CHAP TER 1 3. 1 Vehicle motion control

VACUUM

BOOST

BRAKE ISOLATION

PEDAL VALVE

MASTER B

CYLINDER

A

MOTOR WHEEL

APPLY CYLINDER

VALVE

PUMP

CV 1

SET I

M RELEASE

WHEEL CV 2

SPEED ACC VALVE

CONTROLLER A

SENSOR ACCUM

R

BRAKE

PRESSURE

SENSOR THROTTLE

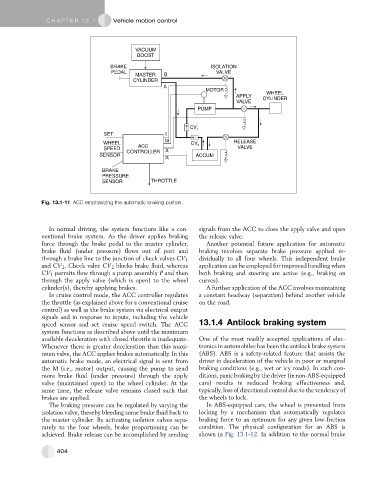

Fig. 13.1-11 ACC emphasizing the automatic braking portion.

In normal driving, the system functions like a con- signals from the ACC to close the apply valve and open

ventional brake system. As the driver applies braking the release valve.

force through the brake pedal to the master cylinder, Another potential future application for automatic

brake fluid (under pressure) flows out of port and braking involves separate brake pressure applied in-

through a brake line to the junction of check valves CV 1 dividually to all four wheels. This independent brake

and CV 2 . Check valve CV 2 blocks brake fluid, whereas application can be employed for improved handling when

CV 1 permits flow through a pump assembly P and then both braking and steering are active (e.g., braking on

through the apply valve (which is open) to the wheel curves).

cylinder(s), thereby applying brakes. A further application of the ACC involves maintaining

In cruise control mode, the ACC controller regulates a constant headway (separation) behind another vehicle

the throttle (as explained above for a conventional cruise on the road.

control) as well as the brake system via electrical output

signals and in response to inputs, including the vehicle

speed sensor and set cruise speed switch. The ACC 13.1.4 Antilock braking system

system functions as described above until the maximum

available deceleration with closed throttle is inadequate. One of the most readily accepted applications of elec-

Whenever there is greater deceleration than this maxi- tronics in automobiles has been the antilock brake system

mum valve, the ACC applies brakes automatically. In this (ABS). ABS is a safety-related feature that assists the

automatic brake mode, an electrical signal is sent from driver in deceleration of the vehicle in poor or marginal

the M (i.e., motor) output, causing the pump to send braking conditions (e.g., wet or icy roads). In such con-

more brake fluid (under pressure) through the apply ditions, panic braking by the driver (in non-ABS-equipped

valve (maintained open) to the wheel cylinder. At the cars) results in reduced braking effectiveness and,

same time, the release valve remains closed such that typically, loss of directional control due to the tendency of

brakes are applied. the wheels to lock.

The braking pressure can be regulated by varying the In ABS-equipped cars, the wheel is prevented from

isolation valve, thereby bleeding some brake fluid back to locking by a mechanism that automatically regulates

the master cylinder. By activating isolation valves sepa- braking force to an optimum for any given low-friction

rately to the four wheels, brake proportioning can be condition. The physical configuration for an ABS is

achieved. Brake release can be accomplished by sending shown in Fig. 13.1-12. In addition to the normal brake

404