Page 753 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 753

CHAP TER 2 2. 1 Exterior noise: Assessment and control

20 log (Sc / Sp)

Xc SPL 1 - SPL 2 0

Sp 1 2 dB

Sc

0 1 2 3

2 Xc f/c

2 Xp f/c

1 2 3

SPL 1 - SPL 2

Xp 0

dB

Sc 1 Sp 2

20 log (Sp/Sc)

0

Xs

M = 0 M = 0 M = 0

SPL 1 - SPL 2 0

1 2 dB

0 M > 0 1 M > 0 2 M > 0 3

2 Xc f/c

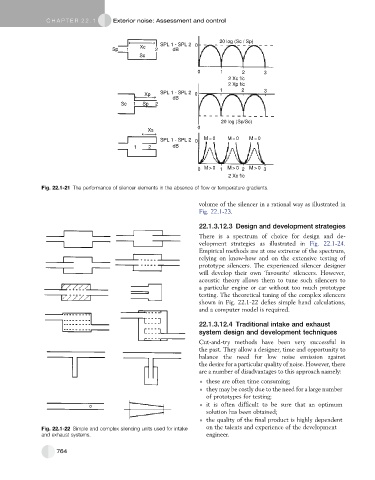

Fig. 22.1-21 The performance of silencer elements in the absence of flow or temperature gradients.

volume of the silencer in a rational way as illustrated in

Fig. 22.1-23.

22.1.3.12.3 Design and development strategies

There is a spectrum of choice for design and de-

velopment strategies as illustrated in Fig. 22.1-24.

Empirical methods are at one extreme of the spectrum,

relying on know-how and on the extensive testing of

prototype silencers. The experienced silencer designer

will develop their own ‘favourite’ silencers. However,

acoustic theory allows them to tune such silencers to

a particular engine or car without too much prototype

testing. The theoretical tuning of the complex silencers

shown in Fig. 22.1-22 defies simple hand calculations,

and a computer model is required.

22.1.3.12.4 Traditional intake and exhaust

system design and development techniques

Cut-and-try methods have been very successful in

the past. They allow a designer, time and opportunity to

balance the need for low noise emission against

the desire for a particular quality of noise. However, there

are a number of disadvantages to this approach namely:

these are often time consuming;

they may be costly due to the need for a large number

of prototypes for testing;

it is often difficult to be sure that an optimum

solution has been obtained;

the quality of the final product is highly dependent

Fig. 22.1-22 Simple and complex silencing units used for intake on the talents and experience of the development

and exhaust systems. engineer.

764