Page 52 - Biaxial Multiaxial Fatigue and Fracture

P. 52

Evaluation of Fatigue of Fillet Welded Joints in Vehicle Components Under Multiaxial Service Loads 31

Failure -cnl tical locations

/

::

- __ -->:- ~

complete submodel . * \ +* c Intersechon of weld root

c

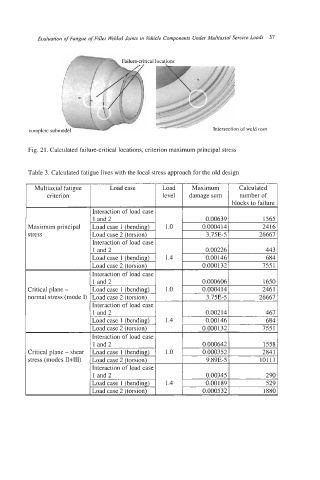

Fig. 21. Calculated failure-critical locations, criterion maximum principal stress

Table 3. Calculated fatigue lives with the local stress approach for the old design

Maximum Calculated

criterion level damage sum number of

blocks to failure

1 and 2 0.00639

Maximum principal 0.0004 I4

stress 3.75E-5 26667

0.00226

0.00 146

0.0001 32 755 1

Interaction of load case

1 and2 0.000606 1650

Critical plane - Load case 1 (bending) 1.0 0.0004 14 246 1

normal stress (mode I) Load case 2 (torsion) 3.75E-5 26667

Interaction of load case

1 and 2 0.00214 I 467

0.00146

0.000132

Interaction of load case

1 and2 0.000642

Critical plane - shear Load case 1 (bending) 1.0 0.000352

stress (modes n+m) Load case 2 (torsion) 9.89E-5 101 11

Interaction of load case

1 and 2 0.00345 290

Load case 1 (bending) 1.4 0.001 89 529

Load case 2 (torsion) 0.000532 1880