Page 456 - Cascade_Biocatalysis_Integrating_Stereoselective_and_Environmentally_Friendly_Reactions

P. 456

432 19 Chemoenzymatic Multistep One-Pot Processes

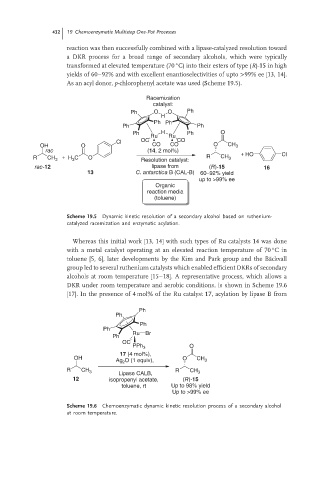

reaction was then successfully combined with a lipase-catalyzed resolution toward

a DKR process for a broad range of secondary alcohols, which were typically

◦

transformed at elevated temperature (70 C) into their esters of type (R)-15 in high

yields of 60–92% and with excellent enantioselectivities of upto >99% ee [13, 14].

As an acyl donor, p-chlorophenyl acetate was used (Scheme 19.5).

Racemization

catalyst:

Ph O O Ph

H

Ph Ph

Ph Ph

Ph H Ph O

Ru Ru

Cl OC CO

OH O CO CO O CH 3

rac (14, 2 mol%) + HO

R CH 3 + H 3 C O Resolution catalyst: R CH 3 Cl

rac-12 lipase from (R)-15 16

13 C. antarctica B (CAL-B) 60–92% yield

up to >99% ee

Organic

reaction media

(toluene)

Scheme 19.5 Dynamic kinetic resolution of a secondary alcohol based on ruthenium-

catalyzed racemization and enzymatic acylation.

Whereas this initial work [13, 14] with such types of Ru catalysts 14 was done

◦

with a metal catalyst operating at an elevated reaction temperature of 70 Cin

toluene [5, 6], later developments by the Kim and Park group and the B¨ ackvall

group led to several ruthenium catalysts which enabled efficient DKRs of secondary

alcohols at room temperature [15–18]. A representative process, which allows a

DKR under room temperature and aerobic conditions, is shown in Scheme 19.6

[17]. In the presence of 4 mol% of the Ru catalyst 17, acylation by lipase B from

Ph

Ph

Ph

Ph

Ru Br

Ph

OC

PPh 3 O

17 (4 mol%),

OH Ag 2 O (1 equiv), O CH 3

R CH 3 Lipase CALB, R CH 3

12 isopropenyl acetate, (R)-15

toluene, rt Up to 98% yield

Up to >99% ee

Scheme 19.6 Chemoenzymatic dynamic kinetic resolution process of a secondary alcohol

at room temperature.