Page 419 - Boiler_Operators_Handbook,_Second_Edition

P. 419

404 Boiler Operator’s Handbook

arm and connecting rod flipping.

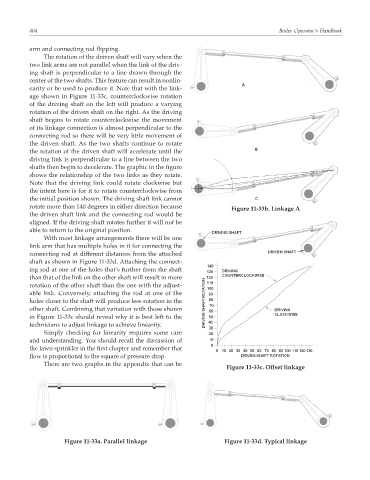

The rotation of the driven shaft will vary when the

two link arms are not parallel when the link of the driv-

ing shaft is perpendicular to a line drawn through the

center of the two shafts. This feature can result in nonlin-

earity or be used to produce it. Note that with the link-

age shown in Figure 11-33c, counterclockwise rotation

of the driving shaft on the left will produce a varying

rotation of the driven shaft on the right. As the driving

shaft begins to rotate counterclockwise the movement

of its linkage connection is almost perpendicular to the

connecting rod so there will be very little movement of

the driven shaft. As the two shafts continue to rotate

the rotation of the driven shaft will accelerate until the

driving link is perpendicular to a line between the two

shafts then begin to decelerate. The graphic in the figure

shows the relationship of the two links as they rotate.

Note that the driving link could rotate clockwise but

the intent here is for it to rotate counterclockwise from

the initial position shown. The driving shaft link cannot

rotate more than 140 degrees in either direction because

Figure 11-33b. Linkage A

the driven shaft link and the connecting rod would be

aligned. If the driving shaft rotates further it will not be

able to return to the original position.

With most linkage arrangements there will be one

link arm that has multiple holes in it for connecting the

connecting rod at different distances from the attached

shaft as shown in Figure 11-33d. Attaching the connect-

ing rod at one of the holes that’s further from the shaft

than that of the link on the other shaft will result in more

rotation of the other shaft than the one with the adjust-

able link. Conversely, attaching the rod at one of the

holes closer to the shaft will produce less rotation in the

other shaft. Combining that variation with those shown

in Figure 11-33c should reveal why it is best left to the

technicians to adjust linkage to achieve linearity.

Simply checking for linearity requires some care

and understanding. You should recall the discussion of

the lawn sprinkler in the first chapter and remember that

flow is proportional to the square of pressure drop.

There are two graphs in the appendix that can be

Figure 11-33c. Offset linkage

Figure 11-33a. Parallel linkage Figure 11-33d. Typical linkage