Page 431 - Boiler_Operators_Handbook,_Second_Edition

P. 431

416 Boiler Operator’s Handbook

gas which always introduced a problem when there was circuit. The analyzer didn’t work very well while we

any amount of oxygen in the water. The sampling sys- were blowing tubes and indicated low oxygen so the air

tems had to operate at high velocity to reduce the time flow went a bit high but the analyzer quit failing every

between analysis and a response to a change in burner month.

operation so leaks in the sample piping was always a Regular failures of the analyzers and drifting of

concern. the calibration compelled me to provide an air fuel ratio

The advent of the zirconium oxide analyzer made adjustment independent of the oxygen trim control and

oxygen trim possible on even small commercial boilers really limit the trim control range so an analyzer failure

because the analyzer can be mounted in the boiler or didn’t produce a hazardous situation or a lot of waste.

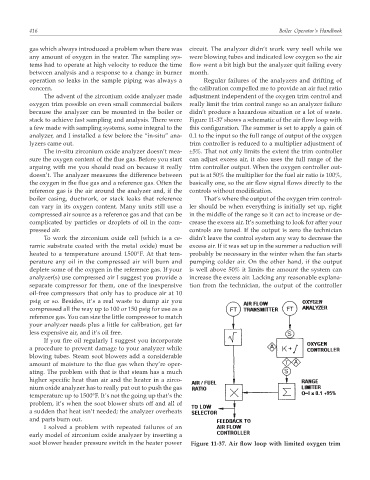

stack to achieve fast sampling and analysis. There were Figure 11-37 shows a schematic of the air flow loop with

a few made with sampling systems, some integral to the this configuration. The summer is set to apply a gain of

analyzer, and I installed a few before the “in-situ” ana- 0.1 to the input so the full range of output of the oxygen

lyzers came out. trim controller is reduced to a multiplier adjustment of

The in-situ zirconium oxide analyzer doesn’t mea- ±5%. That not only limits the extent the trim controller

sure the oxygen content of the flue gas. Before you start can adjust excess air, it also uses the full range of the

arguing with me you should read on because it really trim controller output. When the oxygen controller out-

doesn’t. The analyzer measures the difference between put is at 50% the multiplier for the fuel air ratio is 100%,

the oxygen in the flue gas and a reference gas. Often the basically one, so the air flow signal flows directly to the

reference gas is the air around the analyzer and, if the controls without modification.

boiler casing, ductwork, or stack leaks that reference That’s where the output of the oxygen trim control-

can vary in its oxygen content. Many units still use a ler should be when everything is initially set up, right

compressed air source as a reference gas and that can be in the middle of the range so it can act to increase or de-

complicated by particles or droplets of oil in the com- crease the excess air. It’s something to look for after your

pressed air. controls are tuned. If the output is zero the technician

To work the zirconium oxide cell (which is a ce- didn’t leave the control system any way to decrease the

ramic substrate coated with the metal oxide) must be excess air. If it was set up in the summer a reduction will

heated to a temperature around 1500°F. At that tem- probably be necessary in the winter when the fan starts

perature any oil in the compressed air will burn and pumping colder air. On the other hand, if the output

deplete some of the oxygen in the reference gas. If your is well above 50% it limits the amount the system can

analyzer(s) use compressed air I suggest you provide a increase the excess air. Lacking any reasonable explana-

separate compressor for them, one of the inexpensive tion from the technician, the output of the controller

oil-free compressors that only has to produce air at 10

psig or so. Besides, it’s a real waste to dump air you

compressed all the way up to 100 or 150 psig for use as a

reference gas. You can size the little compressor to match

your analyzer needs plus a little for calibration, get far

less expensive air, and it’s oil free.

If you fire oil regularly I suggest you incorporate

a procedure to prevent damage to your analyzer while

blowing tubes. Steam soot blowers add a considerable

amount of moisture to the flue gas when they’re oper-

ating. The problem with that is that steam has a much

higher specific heat than air and the heater in a zirco-

nium oxide analyzer has to really put out to push the gas

temperature up to 1500°F. It’s not the going up that’s the

problem, it’s when the soot blower shuts off and all of

a sudden that heat isn’t needed; the analyzer overheats

and parts burn out.

I solved a problem with repeated failures of an

early model of zirconium oxide analyzer by inserting a

soot blower header pressure switch in the heater power Figure 11-37. Air flow loop with limited oxygen trim