Page 242 - Buried Pipe Design

P. 242

216 Chapter Four

TABLE 4.8 Number of Cycles to Failure for Tests Two,Three, and Four

Test Two Test Three Test Four

Cycles to Cycles to Cycles to

Pipe # failure Pipe # failure Pipe # failure

3 3.29E6 2 36,300 4 262,711

4 9.67E6 1 43,900 5 273,881

1,2,5 >11.E6 3, 4, 5 47,400 2 280,501

1, 3 284,029

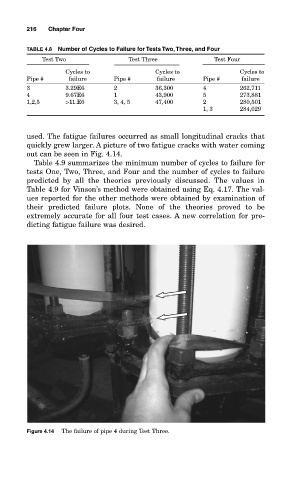

used. The fatigue failures occurred as small longitudinal cracks that

quickly grew larger. A picture of two fatigue cracks with water coming

out can be seen in Fig. 4.14.

Table 4.9 summarizes the minimum number of cycles to failure for

tests One, Two, Three, and Four and the number of cycles to failure

predicted by all the theories previously discussed. The values in

Table 4.9 for Vinson’s method were obtained using Eq. 4.17. The val-

ues reported for the other methods were obtained by examination of

their predicted failure plots. None of the theories proved to be

extremely accurate for all four test cases. A new correlation for pre-

dicting fatigue failure was desired.

Figure 4.14 The failure of pipe 4 during Test Three.