Page 32 - Cam Design Handbook

P. 32

THB1 8/15/03 2:42 PM Page 20

20 CAM DESIGN HANDBOOK

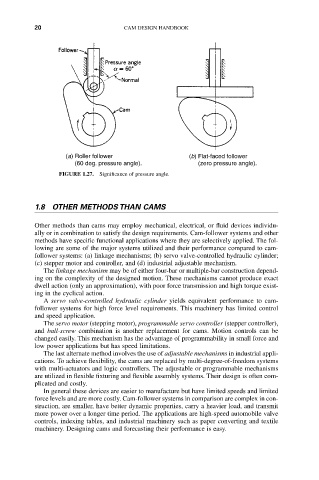

(a) Roller follower (b) Flat-faced follower

(60 deg. pressure angle). (zero pressure angle).

FIGURE 1.27. Significance of pressure angle.

1.8 OTHER METHODS THAN CAMS

Other methods than cams may employ mechanical, electrical, or fluid devices individu-

ally or in combination to satisfy the design requirements. Cam-follower systems and other

methods have specific functional applications where they are selectively applied. The fol-

lowing are some of the major systems utilized and their performance compared to cam-

follower systems: (a) linkage mechanisms; (b) servo valve-controlled hydraulic cylinder;

(c) stepper motor and controller, and (d) industrial adjustable mechanism.

The linkage mechanism may be of either four-bar or multiple-bar construction depend-

ing on the complexity of the designed motion. These mechanisms cannot produce exact

dwell action (only an approximation), with poor force transmission and high torque exist-

ing in the cyclical action.

A servo valve-controlled hydraulic cylinder yields equivalent performance to cam-

follower systems for high force level requirements. This machinery has limited control

and speed application.

The servo motor (stepping motor), programmable servo controller (stepper controller),

and ball-screw combination is another replacement for cams. Motion controls can be

changed easily. This mechanism has the advantage of programmability in small force and

low power applications but has speed limitations.

The last alternate method involves the use of adjustable mechanisms in industrial appli-

cations. To achieve flexibility, the cams are replaced by multi-degree-of-freedom systems

with multi-actuators and logic controllers. The adjustable or programmable mechanisms

are utilized in flexible fixturing and flexible assembly systems. Their design is often com-

plicated and costly.

In general these devices are easier to manufacture but have limited speeds and limited

force levels and are more costly. Cam-follower systems in comparison are complex in con-

struction, are smaller, have better dynamic properties, carry a heavier load, and transmit

more power over a longer time period. The applications are high-speed automobile valve

controls, indexing tables, and industrial machinery such as paper converting and textile

machinery. Designing cams and forecasting their performance is easy.