Page 257 - Chemical Process Equipment - Selection and Design

P. 257

226 HEAT TRANSFER AND HEAT EXCHANGERS

EXAMPLE 8.17-(continued) interstage vapor = (347-305)/(468-305) = 0.2577 lb/lb,

are shown on the pressure-enthalpy and flow diagrams. Isentropic refrigeration = (452-305)0.7423 = 109.1 Btu/lb,

compression and isenthalpic expansion are taken. Without recycle, work = (495-468)0.2577 + (512-452)0.7423 = 51.5 Btu/lb,

refrigeration = 452-347 = 105 Btu/lb, COP = 109.1/51.5 = 2.12,

work = 512-452 = 60 Btu/lb,

COP = 105/60 = 1.75. which points out the improvement in coefficient of performance by

the interstage recycle.

With recycle,

Evaporator Economizer Condenser Bogart (1981, pp. 44-47); it attains -240°F with a maximum

1.2 MBtu/hr 30" dia. by 6' pressure of 527 psia.

560 lbmollhr

-45 F

270psia REFRIGERANTS

2 psia 98 F v Several refrigerants commonly used above -80°F or so are

compared in Table 8.23. Ethylene and butane also are in use,

particularly in refineries where they are recoverable from the

process streams. Properties of the freons (also known by the trade

name genetrons) are listed in Table 8.24. Freon 12 is listed in both

tables so some comparisons of all of these refrigerants is possible.

The refrigerants of Table 8.23 have similar performance. When

I + I I ammonia or some hydrocarbons are made in the plant, their

election as refrigerants is logical. Usually it is preferred to operate

1-75 F at suction pressures above atmospheric to avoid inleakage of air.

The nonflammability and nontoxicity of the freons is an attractive

quality. Relatively dense vapors such as Ref-12, -22, and -500 are

preferred with reciprocating compressors which then may have

Centrifugal Desuperheater Reciprocating smaller cylinders. For most equipment sizes, Ref-12 or -114 can be

compressor compressors adopted for greater capacity with the same equipment. Ref-22 and

-500 are used with specially built centrifugals to obtain highest

450 HP 450 HP capacities.

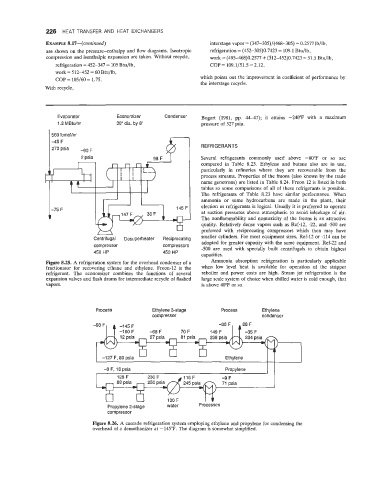

Figure 8.25. A refrigeration system for the overhead condenser of a Ammonia absorption refrigeration is particularly applicable

fractionator for recovering ethane and ethylene. Freon-12 is the when low level heat is available for operation of the stripper

refrigerant. The economizer combines the functions of several reboiler and power costs are high. Steam jet refrigeration is the

expansion valves and flash drums for intermediate recycle of flashed large scale system of choice when chilled water is cold enough, that

vapors. is above 40°F or so.

Process Ethylene 3-stage Process Ethylene

compressor condenser

-93F A -145 F

-160 F -68 F

27 psia

-9 F, 16 psia Propylene

88 psia 71 psia

Propylene 2-stage water Processes

compressor

Figure 8.26. A cascade refrigeration system employing ethylene and propylene for condensing the

overhead of a demethanizer at -145°F. The diagram is somewhat simplified.