Page 616 - Corrosion Engineering Principles and Practice

P. 616

578 C h a p t e r 1 3 C a t h o d i c P r o t e c t i o n 579

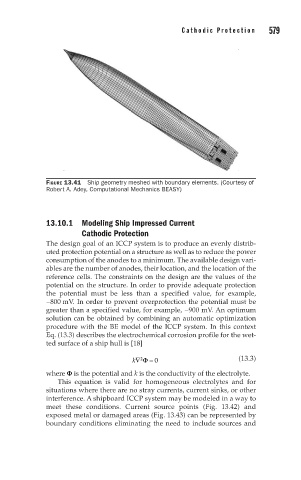

FIGURE 13.41 Ship geometry meshed with boundary elements. (Courtesy of

Robert A. Adey, Computational Mechanics BEASY)

13.10.1 Modeling Ship Impressed Current

Cathodic Protection

The design goal of an ICCP system is to produce an evenly distrib-

uted protection potential on a structure as well as to reduce the power

consumption of the anodes to a minimum. The available design vari-

ables are the number of anodes, their location, and the location of the

reference cells. The constraints on the design are the values of the

potential on the structure. In order to provide adequate protection

the potential must be less than a specified value, for example,

−800 mV. In order to prevent overprotection the potential must be

greater than a specified value, for example, −900 mV. An optimum

solution can be obtained by combining an automatic optimization

procedure with the BE model of the ICCP system. In this context

Eq. (13.3) describes the electrochemical corrosion profile for the wet-

ted surface of a ship hull is [18]

k∇ Φ = 0 (13.3)

2

where F is the potential and k is the conductivity of the electrolyte.

This equation is valid for homogeneous electrolytes and for

situations where there are no stray currents, current sinks, or other

interference. A shipboard ICCP system may be modeled in a way to

meet these conditions. Current source points (Fig. 13.42) and

exposed metal or damaged areas (Fig. 13.43) can be represented by

boundary conditions eliminating the need to include sources and