Page 212 - Defrosting for Air Source Heat Pump

P. 212

206 Defrosting for Air Source Heat Pump

Water collecting tray Water collecting tray

Melted Melted

R1 frost Circuit 1 Refrigerant (liquid) exit R1 frost Circuit 1 Refrigerant exit (liquid)

Melted

Melted

Refrigerant entrance (vapor) R2 Melted Circuit 2 Refrigerant entrance (vapor) R2 Melted Circuit 2

frost

frost

R3 frost Circuit 3 R3 frost Circuit 3

R1= R2= R3 R1 R2 R3

(A) (B)

Melted Melted

frost Circuit 1 Refrigerant exit (liquid) frost Circuit 1 Refrigerant exit (liquid)

Refrigerant entrance (vapor) R1 Melted Circuit 2 Refrigerant entrance (vapor) R1 Melted Circuit 2

frost

frost

R2

R2

Circuit 3

Circuit 3

R3

R3

R1= R2= R3 R1 R2 R3

(C) (D)

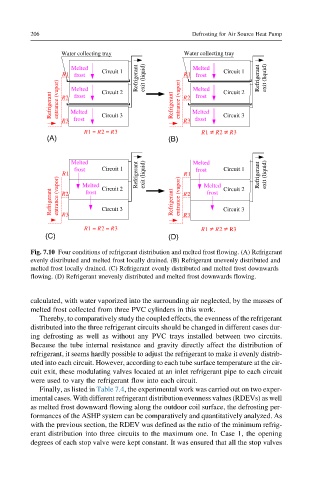

Fig. 7.10 Four conditions of refrigerant distribution and melted frost flowing. (A) Refrigerant

evenly distributed and melted frost locally drained. (B) Refrigerant unevenly distributed and

melted frost locally drained. (C) Refrigerant evenly distributed and melted frost downwards

flowing. (D) Refrigerant unevenly distributed and melted frost downwards flowing.

calculated, with water vaporized into the surrounding air neglected, by the masses of

melted frost collected from three PVC cylinders in this work.

Thereby, to comparatively study the coupled effects, the evenness of the refrigerant

distributed into the three refrigerant circuits should be changed in different cases dur-

ing defrosting as well as without any PVC trays installed between two circuits.

Because the tube internal resistance and gravity directly affect the distribution of

refrigerant, it seems hardly possible to adjust the refrigerant to make it evenly distrib-

uted into each circuit. However, according to each tube surface temperature at the cir-

cuit exit, these modulating valves located at an inlet refrigerant pipe to each circuit

were used to vary the refrigerant flow into each circuit.

Finally, as listed in Table 7.4, the experimental work was carried out on two exper-

imental cases. With different refrigerant distribution evenness values (RDEVs) as well

as melted frost downward flowing along the outdoor coil surface, the defrosting per-

formances of the ASHP system can be comparatively and quantitatively analyzed. As

with the previous section, the RDEV was defined as the ratio of the minimum refrig-

erant distribution into three circuits to the maximum one. In Case 1, the opening

degrees of each stop valve were kept constant. It was ensured that all the stop valves