Page 99 - Defrosting for Air Source Heat Pump

P. 99

Modeling study on uneven defrosting 91

11

10 Circuit 1

Circuit 2

9

Circuit 3

Mass flow rate of refrigerant (g/s) 7 6 5 4

8

2 3 75 s 165 s

1

0 20 40 60 80 100 120 140 160 180 200 220 240

Defrosting time (s)

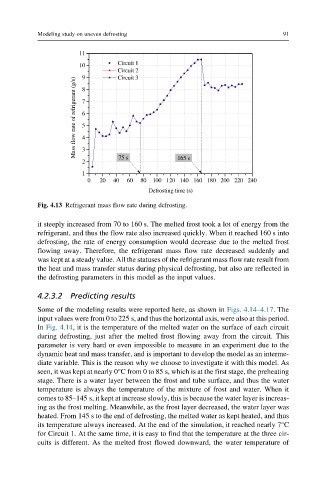

Fig. 4.13 Refrigerant mass flow rate during defrosting.

it steeply increased from 70 to 160 s. The melted frost took a lot of energy from the

refrigerant, and thus the flow rate also increased quickly. When it reached 160 s into

defrosting, the rate of energy consumption would decrease due to the melted frost

flowing away. Therefore, the refrigerant mass flow rate decreased suddenly and

was kept at a steady value. All the statuses of the refrigerant mass flow rate result from

the heat and mass transfer status during physical defrosting, but also are reflected in

the defrosting parameters in this model as the input values.

4.2.3.2 Predicting results

Some of the modeling results were reported here, as shown in Figs. 4.14–4.17.The

input values were from 0 to 225 s, and thus the horizontal axis, were also at this period.

In Fig. 4.14, it is the temperature of the melted water on the surface of each circuit

during defrosting, just after the melted frost flowing away from the circuit. This

parameter is very hard or even impossible to measure in an experiment due to the

dynamic heat and mass transfer, and is important to develop the model as an interme-

diate variable. This is the reason why we choose to investigate it with this model. As

seen, it was kept at nearly 0°C from 0 to 85 s, which is at the first stage, the preheating

stage. There is a water layer between the frost and tube surface, and thus the water

temperature is always the temperature of the mixture of frost and water. When it

comes to 85–145 s, it kept at increase slowly, this is because the water layer is increas-

ing as the frost melting. Meanwhile, as the frost layer decreased, the water layer was

heated. From 145 s to the end of defrosting, the melted water as kept heated, and thus

its temperature always increased. At the end of the simulation, it reached nearly 7°C

for Circuit 1. At the same time, it is easy to find that the temperature at the three cir-

cuits is different. As the melted frost flowed downward, the water temperature of