Page 481 - Design and Operation of Heat Exchangers and their Networks

P. 481

464 Appendix

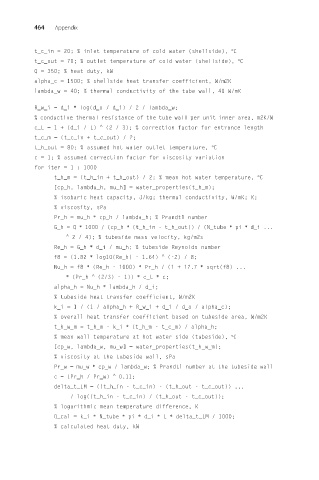

t_c_in = 20; % inlet temperature of cold water (shellside), °C

t_c_out = 70; % outlet temperature of cold water (shellside), °C

Q = 350; % heat duty, kW

alpha_c = 1500; % shellside heat transfer coefficient, W/m2K

lambda_w = 40; % thermal conductivity of the tube wall, 40 W/mK

R_w_i = d_i ∗ log(d_o / d_i) / 2 / lambda_w;

% conductive thermal resistance of the tube wall per unit inner area, m2K/W

c_L = 1 + (d_i / L) ^ (2 / 3); % correction factor for entrance length

t_c_m = (t_c_in + t_c_out) / 2;

t_h_out = 80; % assumed hot water outlet temperature, °C

c = 1; % assumed correction factor for viscosity variation

for iter = 1 : 1000

t_h_m = (t_h_in + t_h_out) / 2; % mean hot water temperature, °C

[cp_h, lambda_h, mu_h] = water_properties(t_h_m);

% isobaric heat capacity, J/kg; thermal conductivity, W/mK; K;

% viscosity, sPa

Pr_h = mu_h ∗ cp_h / lambda_h; % Prandtl number

G_h = Q ∗ 1000 / (cp_h ∗ (t_h_in - t_h_out)) / (N_tube ∗ pi ∗ d_i ...

^

2 / 4); % tubeside mass velocity, kg/m2s

Re_h = G_h ∗ d_i / mu_h; % tubeside Reynolds number

f8 = (1.82 ∗ log10(Re_h) - 1.64) ^ (-2) / 8;

Nu_h = f8 ∗ (Re_h - 1000) ∗ Pr_h / (1 + 12.7 ∗ sqrt(f8) ...

∗ (Pr_h ^ (2/3) - 1)) ∗ c_L ∗ c;

alpha_h = Nu_h ∗ lambda_h / d_i;

% tubeside heat transfer coefficient, W/m2K

k_i =1/(1/ alpha_h + R_w_i + d_i / d_o / alpha_c);

% overall heat transfer coefficient based on tubeside area, W/m2K

t_h_w_m = t_h_m - k_i ∗ (t_h_m - t_c_m) / alpha_h;

% mean wall temperature at hot water side (tubeside), °C

[cp_w, lambda_w, mu_w] = water_properties(t_h_w_m);

% viscosity at the tubeside wall, sPa

Pr_w = mu_w ∗ cp_w / lambda_w; % Prandtl number at the tubeside wall

c = (Pr_h / Pr_w) ^ 0.11;

delta_t_LM = ((t_h_in - t_c_in) - (t_h_out - t_c_out)) ...

/ log((t_h_in - t_c_in) / (t_h_out - t_c_out));

% logarithmic mean temperature difference, K

Q_cal = k_i ∗ N_tube ∗ pi ∗ d_i ∗ L ∗ delta_t_LM / 1000;

% calculated heat duty, kW