Page 482 - Design and Operation of Heat Exchangers and their Networks

P. 482

Appendix 465

s = (1 - Q_cal / Q) ∗ (t_h_in - t_h_out);

% outlet temperature deviation of hot water, K

t_h_out = t_h_out + s;

if (abs(s) < 1E-6)

break;

end

end

m_h = Q / cp_h / (t_h_in - t_h_out);

fprintf('m_h = %fkg/s\n', m_h);

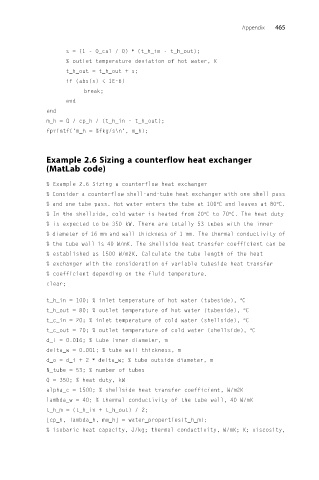

Example 2.6 Sizing a counterflow heat exchanger

(MatLab code)

% Example 2.6 Sizing a counterflow heat exchanger

% Consider a counterflow shell-and-tube heat exchanger with one shell pass

% and one tube pass. Hot water enters the tube at 100°C and leaves at 80°C.

% In the shellside, cold water is heated from 20°Cto 70°C. The heat duty

% is expected to be 350 kW. There are totally 53 tubes with the inner

% diameter of 16 mm and wall thickness of 1 mm. The thermal conductivity of

% the tube wall is 40 W/mK. The shellside heat transfer coefficient can be

% established as 1500 W/m2K. Calculate the tube length of the heat

% exchanger with the consideration of variable tubeside heat transfer

% coefficient depending on the fluid temperature.

clear;

t_h_in = 100; % inlet temperature of hot water (tubeside), °C

t_h_out = 80; % outlet temperature of hot water (tubeside), °C

t_c_in = 20; % inlet temperature of cold water (shellside), °C

t_c_out = 70; % outlet temperature of cold water (shellside), °C

d_i = 0.016; % tube inner diameter, m

delta_w = 0.001; % tube wall thickness, m

d_o = d_i + 2 ∗ delta_w; % tube outside diameter, m

N_tube = 53; % number of tubes

Q = 350; % heat duty, kW

alpha_c = 1500; % shellside heat transfer coefficient, W/m2K

lambda_w = 40; % thermal conductivity of the tube wall, 40 W/mK

t_h_m = (t_h_in + t_h_out) / 2;

[cp_h, lambda_h, mu_h] = water_properties(t_h_m);

% isobaric heat capacity, J/kg; thermal conductivity, W/mK; K; viscosity,